Does a Straight Pipe Add HP? Real Gains or Just Noise Explained

Does a Straight Pipe Add HP? Key Takeaways:

- A straight-pipe exhaust can increase peak horsepower by reducing restrictions, but the gains are typically modest.

- The effectiveness of a straight pipe largely depends on the engine design, header tuning, and any matching intake modifications.

- While removing mufflers and catalytic converters often leads to a noticeable increase in noise, it does not always translate to significant power gains.

- To achieve real performance improvements, it’s essential to use tuned headers, the correct pipe diameter, and make ECU adjustments. Without these, issues with scavenging and air-fuel balance may arise.

- For a deeper understanding of when real gains occur and how to measure them, further sections provide detailed insights.

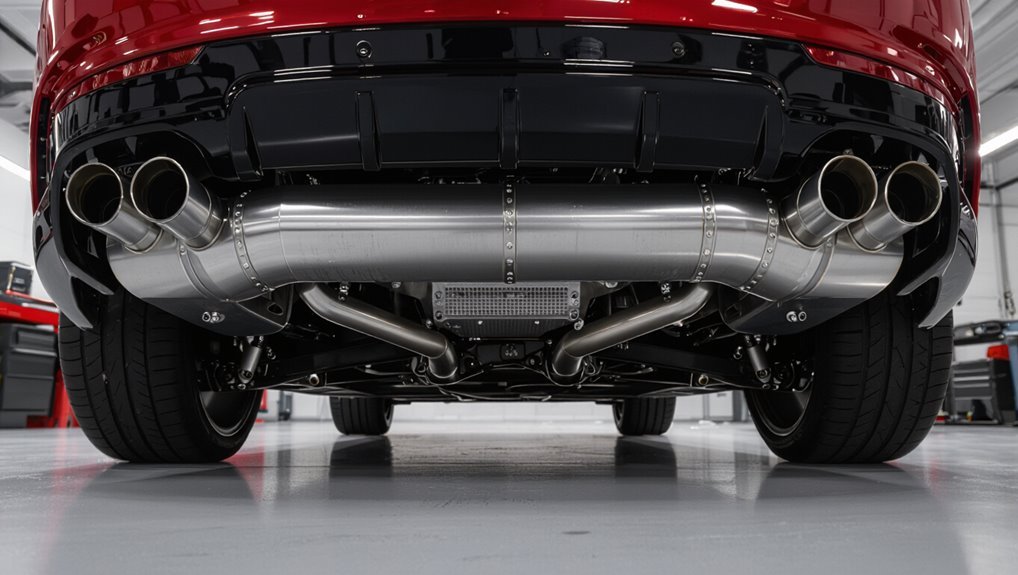

What Is a Straight‑Pipe Exhaust?

A straight‑pipe exhaust is a vehicle exhaust system that removes mufflers, resonators, and often catalytic converters to create an unbroken, minimally restrictive flow path from the engine’s exhaust manifold to the tailpipe.

It eliminates sound‑dampening and backpressure‑modifying components, producing louder, sharper exhaust notes. Construction typically uses continuous-diameter piping with simple bends and welds; materials vary from mild steel to stainless.

Installation can be full‑system or mid‑section only. Straight pipes alter exhaust scavenging characteristics and emissions output but do not inherently include tuning or headers required for reliable power increases.

Legal and environmental implications are commonly associated with their use.

How Does Exhaust Design Affect Engine Power?

Exhaust design influences engine power primarily through gas scavenging and the balance between backpressure and flow.

Properly tuned headers and pipe lengths can use pressure waves to help expel spent gases and draw in fresh charge, improving volumetric efficiency.

Conversely, excessive backpressure or poorly matched flow characteristics can reduce output by hindering exhaust evacuation.

Exhaust Gas Scavenging

When intake valves open, the timing and shape of exhaust pulses can pull spent gases from the cylinder and help refill it with fresh charge; this scavenging effect is controlled by header length, diameter, collector design, and the interaction of pressure waves in the manifold and pipe.

Properly tuned systems use negative pressure waves arriving as the valve opens to extract residual gases and extend the effective volumetric efficiency. Pulse tuning favors specific RPM ranges, so header geometry targets desired power bands.

Mismatched dimensions reduce scavenging, cause reversion, or shift torque away from useful engine speeds, making design critical for real gains.

Backpressure And Flow

Scavenging effectiveness depends on controlled pressure waves, but overall engine performance also hinges on the balance between backpressure and free flow in the exhaust system.

Backpressure is not inherently evil; moderate resistance can maintain exhaust pulse timing, aiding low-end torque and preventing valve overlap issues. Excessive backpressure chokes flow, raising residual gases and reducing peak power.

Conversely, unrestricted free flow can improve high-rpm horsepower but may ruin scavenging and torque if pulse energy dissipates.

Ideal exhaust design matches pipe diameter, length, and muffling to the engine’s cam profile and rpm range, trading peak power for usable torque across the band.

How Do Scavenging and Pulse Tuning Influence Gains?

Scavenging and pulse tuning hinge on precise exhaust pulse timing to use pressure waves for clearing and refilling cylinders.

Header length directly affects the arrival of those waves, with different lengths favoring specific rpm ranges.

Properly timed negative pressure waves lower residual gas and raise volumetric efficiency, producing measurable gains.

Exhaust Pulse Timing

Although often reduced to pipe size and straight-through flow, exhaust performance depends critically on pulse timing: the arrival and reflection of pressure waves in the header determine cylinder evacuation and the extent of any pressure-assisted intake charging.

Properly timed negative pressure waves help scavenge residual gases and draw more fresh charge into the cylinder during valve overlap, improving volumetric efficiency. Conversely, mis-timed or overlapping pulses can raise backpressure or disrupt scavenging, negating gains.

Pulse timing is influenced by exhaust gas velocity, manifold geometry, and engine speed; optimizing those factors yields measurable torque and power benefits without relying solely on increased pipe diameter.

Header Length Effects

Having established how pulse timing affects evacuation and intake charging, attention turns to header length and its role in shaping those pulses.

Header length determines the arrival timing of reflected pressure waves at the exhaust port, enabling constructive interference that aids scavenging or destructive interference that hinders it.

Shorter primaries favor high-rpm power by promoting rapid pulse propagation; longer primaries can enhance midrange torque by delaying reflections to match slower engine speeds.

Equal-length headers preserve pulse regularity across cylinders, improving tunability.

Practical gains depend on engine geometry, cam timing, and desired powerband, so measured testing validates theoretical expectations.

Cylinder Pressure Waves

When exhaust valves open, pressure waves travel down the header and reflect at changes in area or terminations, returning as timed pressure pulses that either help evacuate the cylinder or impede flow.

Cylinder pressure waves determine scavenging effectiveness: a negative pulse arriving during valve overlap assists extraction and draws fresh charge, boosting volumetric efficiency and potential torque. Conversely, a positive pulse can hinder outflow, raising residuals and reducing power.

Pulse tuning depends on pipe length, diameter, engine speed and valve timing; ideal tuning targets aimed rpm bands. Straight pipes alter reflection points and amplitudes, so gains require matching wave behavior to engine characteristics.

Common Claims About Straight Pipes : Are They True?

Many enthusiasts claim that installing a straight pipe will instantly boost horsepower, improve throttle response, and produce dramatic sound changes, but each assertion should be evaluated against how exhaust flow, backpressure, and engine tuning actually interact.

Straight pipes can alter sound markedly, often increasing volume and changing tone, which is reliably true.

Power gains, however, depend on engine type, cam timing, intake design, and whether the engine’s tuning matches altered flow; gains are seldom universal.

Throttle feel may change subjectively due to different pressure dynamics, but measurable improvements require coordinated tuning.

Claims of blanket performance boosts are consequently overstated.

When Can a Straight Pipe Actually Reduce Backpressure?

How, and under what conditions, can replacing a restrictive exhaust with a straight pipe actually lower backpressure?

When the original system has sharp constrictions, collapsed sections, or overly restrictive mufflers, a straight pipe of equal or larger cross-section and smoother bends reduces flow resistance.

Improvements appear when flow velocity is maintained, pulse interference is minimized, and the engine’s breathing is otherwise unimpeded.

Measured reductions are most notable at high RPM or under sustained load where exhaust volume is greatest.

- Remove sharp restrictions and small-diameter sections

- Smooth bends and consistent cross-sectional area

- Eliminate packing or restrictive muffler chambers

Why Less Backpressure Often Doesn’t Increase Power

Removing backpressure alone can fail to raise horsepower because the engine often relies on a specific amount of backpressure for exhaust scavenging and pulse tuning.

Without the right pressure profile, exhaust gases may not evacuate cylinders efficiently and intake filling can suffer.

Consequently, simply straightening the pipe can disrupt tuned pulses and limit any net power gain.

Reduced Backpressure Limits Benefits

Although reducing exhaust backpressure can seem beneficial in isolation, it often fails to produce measurable horsepower gains because internal combustion engines rely on a balance of scavenging, exhaust pulse tuning, and intake pressures.

Reduced backpressure can lower low-end torque, upset runner tuning, and reveal restrictive intake or cam limits, so peak numbers may remain unchanged.

Practical gains require matched changes across the system; otherwise, power plateaus or shifts in the torque curve occur.

Emphasis should be on measured results rather than assumptions when replacing restrictive components with freer-flowing ones.

- Low-end torque loss

- Intake or cam limits exposed

- Peak power unchanged

Scavenging And Pulse Tuning

Many engines depend on precisely timed exhaust pulses to pull spent gases from the cylinder and help draw in fresh charge, a process called scavenging; altering backpressure disrupts that timing and can reduce the effectiveness of pulse tuning. The result may be slower gas evacuation, reduced volumetric efficiency, and uneven torque. Changes to header length, diameter, or straight pipes shift pulse arrival, so simple backpressure reduction can hurt midrange power even if peak numbers rise. Tuned systems balance reflected pressure waves; indiscriminate straight piping removes that control, trading usable torque for noisy peaks.

| Pulse timing | Effect |

|---|---|

| Header length | Arrival shift |

| Backpressure | Reflection change |

| Scavenging | Evacuation impact |

| Torque | Usable loss |

How Header Length and Collector Design Change Performance

When engine designers alter header length and collector geometry, they change the timing and magnitude of exhaust pulse interactions, which in turn shifts effective scavenging, backpressure, and the engine’s torque curve.

Shorter primaries favor high-rpm power by reducing pulse overlap and raising scavenging frequency, while longer primaries boost low-end torque through stronger negative pressure waves timed to intake events.

Collector shape and merge angle affect wave reflection and flow merging; a gradual merge preserves velocity, a tight merge increases scavenging pulses, and stepped collectors tune specific rpm ranges.

Designers balance lengths and collector area to target desired torque band and transient response.

- Short primaries: high-rpm focus, less overlap

- Long primaries: low-end torque, stronger negative waves

- Collector merge: controls pulse reflection and velocity retention

How Mufflers, Resonators, and X‑Pipes Affect Flow

Often overlooked in tuning conversations, mufflers, resonators, and X‑pipes play distinct roles in shaping exhaust flow and pressure wave behavior beyond simple sound control.

Mufflers trade minimal backpressure for attenuation by forcing gas through chambers or baffles; well‑designed units preserve velocity while reducing drone.

Resonators tune midband frequencies and smooth pulses, slightly improving scavenging by reducing reflected pressure spikes.

X‑pipes merge paired headers to promote scavenging balance between banks, smoothing pulses and raising high‑rpm flow compared with H‑pipes.

Each component alters pulse timing and effective pressure recovery; careful selection matches engine character, cam timing, and desired torque curve.

Catalytic Converters: Power Impact and Removal Risks

A catalytic converter influences both exhaust flow and engine management, trading a small amount of restriction for the chemical conversion of harmful gases.

It can slightly reduce peak horsepower by adding backpressure, but modern designs minimize losses; removal may prompt the ECU to adjust fueling, sometimes negating any theoretical gain.

Legal, emissions, and inspection consequences are significant; sensor and check-engine issues commonly arise after removal.

For most street cars, the performance tradeoff is small compared to legal risk and drivability impacts.

- Small measurable power loss from backpressure and heat retention

- ECU adaptations and sensor errors after removal

- Legal and emissions violations, inspections affected

Which Engine Types Benefit Most From Free‑Flowing Exhaust?

Which engines gain the most from a free‑flowing exhaust depends primarily on their breathing characteristics and tuning.

High‑revving naturally aspirated engines with camshaft profiles and intake systems designed for volumetric efficiency benefit significantly: reduced backpressure helps maintain flow at elevated RPMs, improving top‑end horsepower.

Engines with aggressive timing and wideband tuning can extract gains when exhaust scavenging and pulse tuning are optimized. Multi‑valve, high‑flow cylinder heads also respond well.

Conversely, engines relying on low‑end torque, tight scavenging requirements, or forced induction tuning usually need tailored manifold and pipe designs rather than an unrestricted straight pipe to realize useful power increases.

Which Engines Rarely Gain From a Straight Pipe?

While high‑revving naturally aspirated engines often respond well to freer exhaust flow, many powerplants see little or no benefit from a straight pipe.

Turbocharged engines rely on backpressure to aid turbine speed and scavenging; removing restrictions can harm spool and low‑end torque.

Modern engines with sophisticated ECU tuning and variable exhaust geometry are calibrated for specific backpressure and length, so gains are unlikely without retune and hardware changes.

Small displacement, low‑revving engines often trade torque for higher‑rpm power, making straight pipes counterproductive.

Heavy duty diesels depend on exhaust aftertreatment and backpressure for proper regeneration, so straight‑piping is detrimental.

- Turbocharged engines

- Modern ECU‑controlled engines

- Low‑revving diesels

Straight‑Pipe Horsepower: Realistic Gains You Can Expect

When evaluating straight‑pipe horsepower, realistic gains typically fall into a modest range rather than delivering dramatic increases, and expectations should be set according to engine type, tuning, and RPM band.

Measured improvements often appear as single‑digit percent increases on naturally aspirated engines, primarily at higher RPM where backpressure limits flow.

Turbocharged and supercharged systems frequently see negligible or negative changes unless boost dynamics and manifold pressures are retuned.

Gains depend on header design, collector size, and downstream restrictions; proper ECU calibration can recover or magnify benefits.

Why Dyno Numbers Vary Between Shops and Setups

Because dyno results depend on multiple controllable and environmental factors, identical cars tested at different shops often produce different numbers.

Differences stem from dynamometer type, calibration, and inertia; ambient conditions like temperature, pressure, and humidity; and testing procedures such as gearing, tire pressure, and engine warm‑up.

Operators’ choices about smoothing, rolling resistance compensation, and whether to correct to standard conditions further shift reported peak and curve shapes.

Interpreting results requires recognizing these variables rather than trusting raw figures. Consistent methodology across runs gives meaningful comparisons; without it, variance can obscure true hardware effects.

- dyno hardware and calibration

- ambient environmental factors

- testing procedures and corrections

How to Test Gains Properly on a Chassis Dyno?

To verify claimed gains on a chassis dyno, establish a repeatable, controlled protocol before any hardware changes are made.

The technician documents ambient conditions, fuel level, tire pressure, gear selection, and drivetrain losses. Baseline runs are repeated until variance is minimal; then the modification is installed and the same sequence repeated.

Use consistent warm‑up procedures, cooling intervals, and datalogging of rpm, torque, and intake temperature. Apply the dyno’s correction factor consistently and report both raw and corrected figures.

Present statistical spread (mean, standard deviation) and avoid single-run comparisons to distinguish real gains from measurement noise.

How to Test Gains Properly on an Engine Dyno?

Although an engine dyno isolates the powerplant from vehicle variables, proper testing still requires a strict, repeatable protocol to produce meaningful comparisons. The test setup must document engine temperature, oil and coolant conditions, fuel quality, intake and exhaust routing, and dynamometer calibration.

Baseline runs establish repeatability; subsequent changes are introduced singly and retested. Data smoothing and averaging across multiple steady-state or sweep runs reduce measurement noise. Corrections for ambient pressure and humidity are applied consistently.

Record raw logs and note all hardware or ECU changes to enable reproducible verification.

- Repeatable environmental and engine conditions

- Single-variable change methodology

- Multiple runs with averaging and correction

Why Road Testing Can Be Misleading

Why do perceived gains on the street often differ from controlled measurements? Road testing introduces variables—traffic, slope, wind, fuel quality, and rider perception—that distort outcomes. Driver throttle input and vehicle load vary; instrumentation lacks repeatability. Environmental changes and transient conditions mask small performance differences a straight pipe might produce. Anecdotes and seat-of-pants impressions conflate noise with gain. To interpret road results, isolate variables, repeat runs, and record objective data; otherwise apparent improvements remain unreliable.

| Variable | Effect | Control |

|---|---|---|

| Wind | Alters load | Shelter or average |

| Slope | Changes acceleration | Level course |

| Driver | Inconsistent input | Data logging |

How Intake Changes Interact With a Straight Pipe

Changes to the intake affect how a straight pipe influences engine performance by altering airflow volume, intake air temperature, and the system’s resonance.

Increased airflow can expose limits of the exhaust design, while cooler or warmer intake charge shifts combustion efficiency and detectable gains.

Additionally, intake and exhaust tuning interact through pressure waves and timing, so combined changes can amplify or negate expected horsepower effects.

Airflow Volume Effects

How does a straight pipe interact with altered intake flow volumes? A straight pipe changes downstream resistance but cannot create more air than the intake delivers.

When intake volume increases, the pipe can reduce exhaust backpressure, allowing valves to evacuate cylinders more efficiently; with lower intake flow, benefits are negligible.

Net power depends on balanced intake and exhaust capacities, cam timing, and tuning. Mismatches can shift torque curve, improve high-rpm breathing, or worsen low-rpm response.

Tuned systems and dyno validation reveal real gains versus noise.

- Increased intake volume + low exhaust restriction → better high-rpm power

- Low intake flow → minimal benefit

- Balance required for usable gains

Intake Temperature Changes

After considering intake volume and exhaust restriction, intake air temperature becomes the next variable that determines whether a straight pipe yields measurable gains.

Cooler intake charge increases air density, allowing more oxygen per intake stroke; any exhaust modification that reduces backpressure can marginally influence intake temperatures by altering scavenging and heat transfer.

Conversely, hotter intake air reduces density and can mask small volumetric improvements from a straight pipe.

Practical gains depend on ambient conditions, intercooling effectiveness, and intake routing rather than the exhaust alone.

Measuring intake temperature and density alongside power verifies whether observed changes are thermal or truly flow-related.

Resonance And Tuning

Why does intake tuning matter when a straight pipe is fitted to the exhaust? Changes in exhaust backpressure and pulse timing alter intake resonance, affecting volumetric efficiency across RPM.

A straight pipe can shift pressure wave timing, so intake length and runner geometry that once complemented stock exhaust may no longer align with new pulse frequencies. Without retuning, peak torque can move or flatten, and drivability may suffer despite similar peak horsepower.

Proper intake tuning—runner length, plenum volume, and ECU timing—restores harmonic matching between intake pulses and exhaust scavenging.

- Intake runner length adjustments

- Plenum and resonance chamber tuning

- ECU timing and fuel mapping

Why Tuning Is Often Required After Straight Piping

Because straight piping alters exhaust flow and backpressure, the engine’s air-fuel balance and timing can fall out of their factory-calibrated ranges, making retuning necessary to restore performance and prevent damage.

A changed scavenging effect shifts cylinder filling and scavenges residual gases differently, affecting volumetric efficiency across RPM.

Oxygen sensor feedback and closed-loop fueling may not compensate for altered flow dynamics, risking lean or rich conditions.

Ignition timing optimized for stock backpressure can induce knock or lost torque when flow improves.

Tuning aligns fueling, ignition, and any adaptive strategies to the new exhaust characteristics, safeguarding reliability and realizing usable performance.

What ECU Adjustments Unlock Gains?

What specific ECU changes translate reduced exhaust restriction into measurable power gains? The ECU must recalibrate parameters to exploit improved scavenging and altered backpressure.

Adjustments focus on timing, fueling, and load mapping to safely raise torque and avoid knock. Proper changes prevent limp modes and enable additive gains rather than artifacts.

- Ignition timing: advance in safe windows where knock margins permit to capitalize on improved cylinder evacuation.

- Fuel delivery: transient and steady-state fueling maps refined to match changed volumetric efficiency without rich/lean excursions.

- Load and boost targets: revise load-to-injection and boost control tables for accurate torque requests.

How Does the Air/Fuel Ratio Shift After Exhaust Changes?

Changing to a straight pipe can alter exhaust backpressure and flow, which often shifts the air/fuel ratio toward either richer or leaner depending on engine tuning.

Oxygen sensors and the ECU react to those changes—closed-loop feedback may correct minor shifts, while larger flow increases can outpace the system and leave the mixture altered.

Understanding sensor limits and whether the ECU can adapt is essential to predicting post-modification AFR behavior.

Richer Or Leaner Mixture

How does altering exhaust flow influence the engine’s air/fuel ratio?

Changes in exhaust scavenging and backpressure can shift volumetric efficiency, subtly altering intake air mass and consequently mixture richness. In many cases a freer-flowing pipe can lean the mixture slightly by increasing airflow; conversely, disrupted pulse tuning can enrich pockets of intake charge.

Without invoking sensor or ECU interventions, the mechanical effect is modest but measurable and depends on rpm, cam timing, and manifold design.

- Freer flow often reduces backpressure, tending to lean the mixture at high rpm.

- Loss of scavenging can enrich midrange due to poorer cylinder filling.

- Net shift rarely exceeds a few percent in typical setups.

Sensor And ECU Response

The modest mechanical shifts in volumetric efficiency from altering exhaust flow are quickly interpreted by the vehicle’s feedback systems.

So sensors and the ECU often adjust fueling to restore target air/fuel ratios. Oxygen sensors detect deviation in post-catalyst exhaust composition, prompting the ECU to trim injector pulse width.

Wideband sensors, where present, give more precise corrections across load and RPM, enabling closed-loop and open-loop map adaptations.

Short-term fuel trim compensates immediately; long-term trim can recalibrate learned fuel maps if changes persist.

Resulting AFR shifts are typically small unless the modification dramatically alters pressure waves or removes critical sensors.

When a Straight Pipe Can Cause Drivability Problems

Although a straight pipe can free up exhaust flow and raise peak power, it can also produce drivability issues when the rest of the engine and tuning are not matched to that change.

Mismatched backpressure and altered scavenging can shift torque curves, cause flat spots, and degrade low‑RPM response. The oxygen sensor and ECU may see unexpected readings, prompting corrective fueling that feels jerky or rich.

Emissions systems removal can trigger limp modes on some vehicles. Proper tuning, header length, and resonators often prevent problems; otherwise, perceived gains become tradeoffs in daily usability.

- Reduced low‑end torque and hesitations

- Erratic fueling corrections

- Limp or fault modes

Is Straight‑Piping Legal in Your State?

Whether straight‑piping is permitted varies by state, largely depending on emissions regulations that prohibit removal or alteration of pollution‑control devices.

Local noise ordinances can further restrict exhaust modifications even where emissions rules are lax.

Readers should check both state environmental laws and municipal noise codes before making changes.

State Emissions Regulations

Because vehicle exhaust rules vary widely by state, verifying local emissions regulations is essential before removing catalytic converters or mufflers.

The legal status of straight‑piping often hinges on emissions inspections, tampering laws, and federal standards adopted locally. Some states ban removal of emission control devices outright; others allow modifications if on off‑road or race‑only vehicles.

Penalties range from fines to failed inspections or vehicle registration denial. Owners should consult state motor vehicle agencies and inspection stations, document exemptions where applicable, and consider compliant performance alternatives.

- Check state tampering and emissions statutes

- Confirm inspection and registration impacts

- Seek documented exemptions or compliant upgrades

Local Noise Ordinances

Local noise ordinances play a critical role in determining whether straight‑piping a vehicle is permissible, since many municipalities set decibel limits, time‑of‑day restrictions, and enforcement mechanisms that effectively prohibit excessively loud exhaust modifications.

Municipal codes vary: some specify numeric dB caps measured at property lines, others use subjective “unreasonable” or “disturbing” language enforced by complaints.

Penalties range from fines to impoundment or mandatory repairs. Enforcement intensity differs between residential, commercial, and special districts.

Owners should consult local ordinances and measurement procedures, test exhaust levels with calibrated meters, and consider quieter alternatives or permits before modifying exhaust systems.

How Do Emissions Controls Limit Your Options?

When emissions controls are active, they constrain which exhaust modifications are legal and effective by mandating certain components and flow characteristics.

The presence of catalytic converters, oxygen sensors, and onboard diagnostics forces installers to retain specific placements and backpressure ranges; removing or relocating those parts can trigger faults, emissions failures, or legal penalties.

Performance choices consequently focus on compliant upgrades: higher-flow catalytic converters, tuned headers, and mufflers that preserve sensor signals while optimizing flow.

Owners must balance claimed gains against compliance risk and real-world drivability impacts when choosing modifications.

- Retain sensor locations and oxygen circuit integrity

- Use compliant high-flow catalytic elements

- Apply tuning to match altered flow characteristics

How Catalytic Converter Removal Affects Inspections

How does removing a catalytic converter influence vehicle inspections?

Inspectors typically check for emission control devices; absence of a converter often triggers failure on visual and emissions tests.

OBD-II diagnostics can flag catalyst efficiency codes; a removed unit usually results in stored fault codes and automatic inspection failure where testing includes sensor readings.

Some regions mandate visible component verification during annual or safety inspections; tampering marks or mismatched exhaust sections are noted.

Temporary exemptions or waivers are rare and specific.

Owners seeking compliance must reinstall approved converters or provide documented, legal alternatives to pass inspection and avoid fines.

How Noise Regulations and Local Ordinances Affect Street Legality

Local noise ordinances set maximum decibel levels and specific time windows that can render a straight-piped vehicle illegal to operate on public roads.

Enforcement varies by jurisdiction, ranging from routine patrol checks and noise meters to citizen complaints that trigger inspections.

Penalties can include fines, mandatory repairs, vehicle impoundment, or denial of registration, so owners must match exhaust modifications to local rules.

Local Noise Ordinances

Although a straight pipe can increase exhaust volume and change tone, municipal noise ordinances ultimately determine whether that modification is street legal. Cities and counties set decibel limits, measurement procedures, and enforcement priorities that can make the same exhaust legal in one jurisdiction and a violation next door.

Local ordinances specify where and how measurements occur, time-of-day restrictions, and exemptions for certain vehicles or events. Compliance often depends on documented decibel testing and whether the vehicle meets manufacturer or post‑market limits.

Owners must consult local code before modifying exhaust to avoid noncompliance.

- Measurement location and method

- Time and situational limits

- Specific decibel thresholds

Enforcement And Penalties

Enforcement of noise ordinances typically combines routine patrols, targeted sting operations, and citizen complaints to identify vehicles that exceed permitted decibel limits.

Officers may use handheld or vehicle-mounted sound meters; documented violations often require repeat measurements or standardized testing.

Penalties range from warnings and fines to vehicle impoundment or mandatory muffler installation, depending on jurisdiction and offense history.

Courts or administrative hearings adjudicate contested cases.

Commercial modifications can trigger stricter enforcement.

Repeat or egregious violators face escalating sanctions and possible license points.

Awareness of local codes and documented compliance can prevent fines and preserve a vehicle’s street legality.

Insurance and Warranty Risks of Straight‑Pipe Modifications

How does removing catalytic components and mufflers affect a vehicle’s legal and financial protections?

Removing emissions equipment or aftermarket straight‑pipe work often voids parts of a warranty and can lead insurers to deny claims if the modification contributed to a failure or accident.

Policies may charge higher premiums or exclude coverage for modified vehicles. Documentation, professional installation, and notifying the insurer can mitigate risk but not eliminate it.

- Warranty: manufacturer may deny repair coverage linked to exhaust changes.

- Insurance: claim denials or surcharges if modification is undisclosed.

- Compliance: illegal modifications can trigger fines and affect liability.

What Sound Levels Should You Expect From a Straight Pipe?

Typical decibel ranges for straight‑piped vehicles often fall between 90 and 110 dB at idle and can exceed 120 dB under hard throttle.

Loudness generally increases with RPM and load, producing sharper peaks during acceleration and gear changes.

Legal noise limits and safety considerations vary by jurisdiction and can make such levels noncompliant or hazardous to hearing.

Typical Decibel Ranges

When a vehicle exhaust is converted to a straight pipe, overall sound levels generally rise markedly, with common passenger cars producing between about 90 and 110 dB at wide-open throttle and many performance cars reaching 100–120 dB under aggressive acceleration.

Typical decibel ranges depend on engine size, tuning, and proximity; measurements cited by enthusiasts and limited tests cluster into predictable bands. Short bursts can exceed comfortable thresholds, while cruising levels remain lower.

Listeners should expect variability but prepare for considerably louder operation overall.

- Cruise: ~75–95 dB depending on speed and distance

- WOT: ~90–120 dB

- Idle/low load: ~65–85 dB

RPM-Dependent Loudness

As engine speed rises, a straight pipe amplifies both overall loudness and the prominence of specific frequency bands, producing a predictable shift in perceived volume and tone across the RPM range.

Lower RPMs emphasize deeper, bass-rich pulses; midrange revs bring fuller harmonic content and increased midband SPL; high RPMs drive sharp, high-frequency energy and stronger peak levels.

Measured decibel curves typically slope upward with RPM, showing peaks at engine-order harmonics. Subjective harshness increases where resonances align with valve timing.

Expect dynamic changes rather than a flat increase: sound character and perceived loudness depend on engine tuning, exhaust geometry, and RPM-specific resonance.

Legal And Safety Limits

Because exhaust noise crosses into regulated territory quickly, straight-piped vehicles commonly exceed municipal and state sound limits and can trigger fines, inspection failures, or orders to reinstall mufflers.

Authorities measure decibels at specified distances and RPMs; readings above local limits (often 80–95 dB for street vehicles) lead to violations.

Safety concerns include hearing damage for occupants and reduced audibility of other road users. Insurance and warranty consequences are possible where modifications violate regulations.

Owners should check local statutes, use sound meters or professional testing, and consider resonators or mufflers designed to meet legal thresholds.

- Typical urban limits: 80–90 dB

- Enforcement methods: static and drive-by tests

- Remedies: compliant mufflers, inspections

How to Reduce Loudness Without Killing Flow

Several practical strategies can reduce exhaust loudness while preserving flow by targeting pressure waves and turbulence rather than simply adding restriction.

Engineers recommend Helmholtz resonators tuned to cancel dominant frequencies, multi-chamber mufflers that absorb energy across bands, and perforated core designs that attenuate sound with minimal backpressure.

Smooth gradual bends and equal-length headers reduce destructive interference that creates peaks.

Use of sound-deadening heat-resistant wraps on non-flow surfaces lowers radiated noise without affecting gas dynamics.

Variable bypass valves permit quiet operation at low loads while opening fully at high flow.

Proper installation and periodic inspection maintain performance and avoid unintended resonances.

Weight Savings vs. Power Gains: Which Matters More?

Which yields more real-world performance: shedding weight or adding horsepower? The analysis favors context: lighter vehicles improve handling, braking, and transient response across multiple axes, while horsepower boosts top-end speed and acceleration in specific gears.

Practical gains depend on driving style, vehicle class, and where power is delivered. Weight reduction often provides predictable, drivetrain-independent benefits; power increases can be negated by traction, gearing, or heat.

For most street-driven cars, modest weight loss yields more usable everyday improvement than equivalent peak horsepower gains.

- Improved cornering and braking from lower mass

- Usable acceleration limited by traction and gearing

- Power increases benefit high-speed or track use

Cost Breakdown: Parts, Labor, and Tuning

When evaluating the true expense of replacing a muffler with a straight pipe, owners should separate costs into three clear categories: parts, labor, and tuning.

Parts include pipe sections, flanges, clamps, and any required adapters; material quality and stainless options change prices considerably.

Labor covers fabrication, welding, hanger adjustments, and time at a shop; custom jobs raise hours and rates.

Tuning entails ECU remaps or piggyback modules to optimize fuel and ignition for altered backpressure and flow; dyno validation adds cost but verifies gains.

Summing these yields a realistic budget and informs whether expected performance justifies the expense.

Common Mistakes That Waste Potential Gains

After accounting for parts, labor, and tuning, many owners still miss simple steps that negate expected performance gains.

The article notes overlooked issues: poor installation, ignored supporting mods, and unrealistic expectations. Improper flange sealing, loose hangers, or exhaust leaks erase measurable benefits. Neglecting intake, fueling, or ignition leaves the engine unable to use freer flow.

Expecting dramatic horsepower from a single change misunderstands systems thinking. Maintenance lapses—old spark plugs, clogged filters—also mask gains. Attention to detail and incremental validation prevent wasted effort.

Common mistakes are procedural and avoidable, not inherent flaws of straight-pipe conversions.

- Improper sealing or fitment

- Missing supporting modifications

- Skipping maintenance and validation

How to Choose the Right Exhaust Diameter

Choosing the correct exhaust diameter hinges on matching pipe size to an engine’s flow characteristics to preserve velocity and scavenging.

Too small a pipe creates backpressure and restricts peak flow, while too large a pipe reduces gas speed and low-end torque.

As a result, selection should be based on measured or calculated engine flow and the vehicle’s designated application rather than on a one-size-fits-all rule.

Engine Flow Characteristics

Because exhaust diameter governs how quickly exhaust gases can evacuate the combustion chamber, correct sizing is critical to maximizing power and efficiency.

Engine flow characteristics depend on pulse timing, gas velocity, and pressure waves; they determine scavenging effectiveness and backpressure. Optimizing flow means matching pipe area to expected exhaust mass flow across the rpm range while preserving sufficient velocity for low-end torque.

Engine displacement, cam profile, and target powerband dictate preferred flow behavior. Computational or empirical testing refines choices.

Consider transient response and steady-state flow together to avoid compromises that harm drivability or peak output.

- Pulse timing and scavenging

- Gas velocity versus area

- Pressure wave interactions

Pipe Diameter Tradeoffs

With flow characteristics established, selecting exhaust diameter becomes an exercise in balancing competing goals: sufficient cross-sectional area to prevent choking at high rpm versus maintaining velocity for low-end scavenging and torque.

Larger diameters reduce backpressure and can support greater peak flow, benefiting high-revving engines, but they lower gas speed, weakening pulse energy and midrange torque.

Smaller diameters preserve velocity and improve scavenging at lower speeds but restrict maximum flow, risking power loss as rpm climbs.

Ideal choice considers peak flow demands, target rpm range, and pressure loss versus velocity tradeoffs; conservative compromises often yield the most usable performance.

Application-Specific Matching

When matching exhaust diameter to a specific application, the decision hinges on engine characteristics and planned use: displacement, cam profile, peak rpm, and whether the vehicle prioritizes low-end torque, midrange responsiveness, or top-end power dictate the best bore.

The ideal pipe balances scavenging, gas velocity, and backpressure for designated RPM range. Smaller diameters preserve velocity and torque; larger diameters reduce restriction at high RPM.

Practical selection considers stock vs. built internals, turbo or naturally aspirated setups, and designated gearing or racing class. Choose conservatively, favoring slightly tighter for street use and larger for sustained high-rpm use.

- Small bore: better low-end torque

- Medium bore: balanced midrange

- Large bore: high-rpm top-end gains

When to Use a Straight Section Versus a Tuned System

Deciding between a straight section and a tuned exhaust system hinges on the engine’s designed use and RPM range: a straight section favors unrestricted flow and peak power at high RPM, while a tuned system optimizes pulse timing for broader torque and improved midrange response.

Choice depends on proposed operation: racing engines that spend time at high rpm may gain from minimal restriction, while street, towing, or daily-driven engines benefit from tuned lengths and scavenging for low-to-mid torque.

Packaging, emissions, and noise limits also influence selection.

Combining short straight runs with tuned headers can balance flow and pulse tuning for practical compromises.

Aftermarket Systems That Outperform a Simple Straight Pipe

Although a straight pipe can reduce backpressure, many aftermarket exhaust systems surpass it by combining tuned headers, expansion chambers, and tuned-length midsections to recover pulse energy and broaden the usable powerband.

These systems are engineered to manage scavenging, control reflected pressure waves, and retain low-end torque while allowing high-rpm flow. Manufacturers tune geometry to match engine displacement, cam timing, and exhaust valve characteristics.

Material choice and acoustic packing can influence transient response and drivability. Properly designed systems often outperform a simple straight pipe across a wider rpm range rather than merely boosting peak numbers.

- Tuned header and collector designs

- Expansion chamber or resonator tuning

- Matched midsection lengths

Track Use Versus Street Use: Different Priorities

On the track, maximizing peak power often justifies a straight pipe despite sacrifices to midrange drivability.

On the street, noise, increased heat, and reduced comfort make a straight pipe impractical for daily use.

Legal exposure and higher maintenance demands further widen the tradeoff between competition-focused gains and everyday practicality.

Peak Power vs Drivability

When choosing exhaust and engine tuning for track-focused builds, maximizing peak horsepower often takes precedence over everyday drivability because lap times reward top-end power and high-RPM efficiency.

Conversely, street-oriented setups favor smooth low-end torque, throttle response, and noise control so the car remains usable and compliant in daily traffic.

The tradeoff is deliberate: long, free-flowing headers and straight piping can raise peak torque and power at high rpm but may sacrifice low-speed tractability, throttle modulation, and emissions.

Tuners balance cam timing, intake, and exhaust length to shift the power band toward the designed use without crippling usability.

- Track: high-rpm power, reduced low-end torque

- Street: low-end response, usable power band

- Compromise: targeted tuning and hardware adjustments

Noise, Heat, And Comfort

How loud is too loud depends entirely on context: track rigs tolerate—and often require—high decibel levels and hotter exhaust temps for unrestricted flow, while street cars prioritize cabin comfort, legal limits, and reduced radiant heat. The tradeoff is sensory: racers accept piercing noise and heat for lap-time gains; daily drivers accept mild performance loss to preserve conversation, sleep, and neighbors. Comfort affects perceived performance; constant heat and drone wear on occupants. Choices reflect priorities rather than pure physics.

| Track | Emotion |

|---|---|

| Loud, raw, urgent | Adrenaline |

| Hot, exposed | Focus |

| Street | Quiet, content |

Legal And Maintenance Tradeoffs

Because track-focused modifications often push vehicles beyond standard regulatory and service envelopes, owners must weigh legal exposure and increased maintenance against performance gains.

A straight pipe may improve flow under specific conditions but can violate noise and emissions laws, trigger inspections, and complicate insurance claims. Maintenance intervals shorten: valves, sensors, and exhaust components endure higher stress and require frequent checks.

For those primarily on the street, compliance and reliability often outweigh marginal lap time benefits. Track-only setups accept legal risk and higher upkeep for peak performance, while street-driven choices prioritize durability, legality, and predictable service costs.

- Legal noncompliance risks and enforcement

- Increased inspection and repair frequency

- Insurance and resale implications

Safety and Heat‑Management Concerns With Straight Pipes

Although a straight pipe can increase exhaust flow, it also alters heat distribution and noise levels in ways that raise safety concerns.

Higher exhaust temperatures can concentrate heat near fittings, wiring, or body panels, increasing risk of component damage or fire if shielding is inadequate. Reduced backpressure changes scavenging and can shift hotspots in the exhaust manifold or turbocharger, accelerating wear.

Louder, unattenuated noise impairs hearing and can mask warning sounds or reduce situational awareness, posing risks to riders and bystanders.

Proper heat shielding, routing, and adherence to noise regulations mitigate hazards but require careful engineering and maintenance.

How to Document and Quantify Your Results

Documenting and quantifying the effects of a straight pipe requires consistent, repeatable measurements and clear records of test conditions.

The writer recommends baseline dyno runs, controlled driving tests, and ambient condition logs. Each run should note fuel type, temperature, barometric pressure, and engine load.

Use the same gear and RPM range for comparisons, record multiple runs to calculate averages, and report variance. Present results with raw numbers and corrected figures, and include measurement uncertainty.

Transparency about instrumentation and procedures reduces misinterpretation and separates real changes from test noise.

- Baseline and post-modification averaged runs

- Environmental and procedural parameter log

- Uncertainty and correction method

Case Studies: Modest Gains, Big Gains, and No Gains

Three representative case studies—one showing modest gains, one showing large gains, and one showing no measurable change—illustrate how vehicle-specific factors and testing methodology determine outcomes when a straight pipe is installed.

In the modest case, a turbocharged four-cylinder with minor backpressure reduction gained 4–6 hp on a consistent dyno run after tuning to correct AFR shifts.

The large-gain example involved an older V8 with a restrictive OEM muffler system; removing it plus matching headers revealed 15–20 hp where torque curves improved across the band.

The no-gain scenario featured a modern, well-flowing exhaust car; measurements stayed within test variance.

Alternatives That Often Deliver Better Value Than Straight Piping

When evaluating performance upgrades, several alternatives typically produce more reliable, cost-effective gains than simply installing a straight pipe.

Buyers often achieve measurable improvements by addressing restrictive systems and tuning rather than removing mufflers alone. Targeted parts restore flow where it matters and support safe air/fuel control.

- Cold-air intake or upgraded intake tract for improved volumetric efficiency.

- High-flow catalytic converter or sports cat to reduce backpressure while remaining street-legal.

- ECU remap or piggyback tuner to optimize fueling and ignition for installed hardware.

These options tend to deliver repeatable horsepower, better drivability, and compliance with emissions regulations.

Decision Checklist: Should You Straight‑Pipe Your Car?

Should a straight pipe be added, and under what circumstances is it a sensible choice? The checklist evaluates goals, legalities, and tradeoffs: confirm desired outcome (sound preference vs measurable power), check emissions and noise regulations, verify vehicle warranty and insurance implications, and assess engine and ECU readiness for altered backpressure.

Consider alternatives (cat-back, high-flow cat, tuning) for cost-effectiveness. Factor installation complexity, resale impact, and potential for check-engine lights.

If the owner accepts legal risk, louder exhaust, and likely minimal HP gain without tuning, a straight pipe is defensible; otherwise pursue targeted, emission-compliant upgrades.

Conclusion

A straight‑pipe exhaust can sometimes free horsepower but often trades measurable gains for noise, legal risk, and poor low‑end drivability. Engineers note that exhaust tuning, scavenging, and component matching usually matter more than simply removing mufflers. In short, results vary: a few engines benefit, many lose torque, and some see no change. Buyers should weigh costs, dyno data, and local laws — don’t throw the baby out with the bathwater when chasing a louder roar.