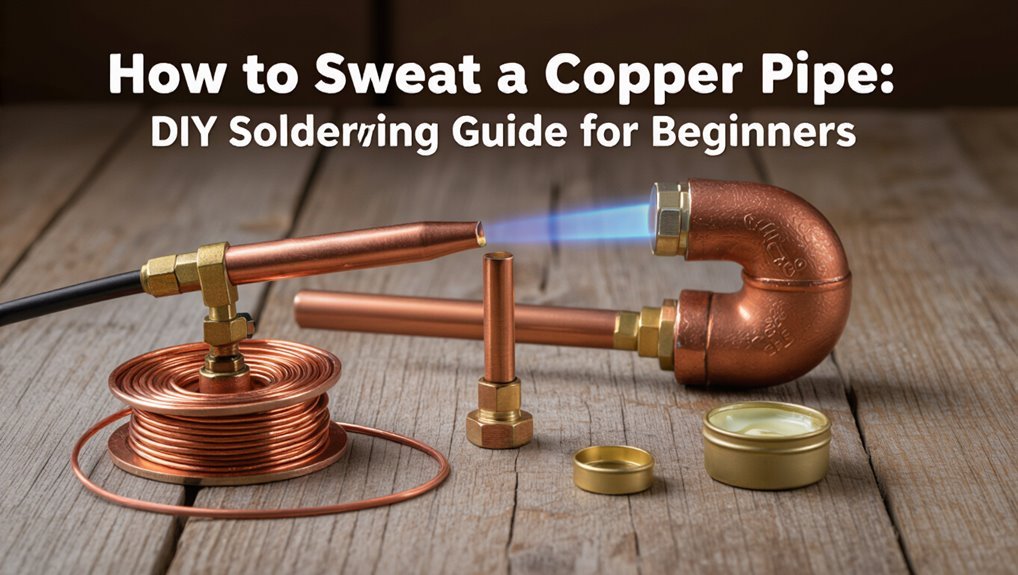

How to Sweat a Copper Pipe: DIY Soldering Guide for Beginners

To sweat a copper pipe, follow these key steps:

- Cut and Deburr the Pipe: Use a pipe cutter to achieve a clean cut and remove any burrs for a smooth surface.

- Clean the Surfaces: Use emery cloth to clean both the pipe and fitting surfaces thoroughly.

- Apply Flux: Coat the cleaned surfaces with a thin layer of paste flux to facilitate solder flow.

- Fit the Joint: Ensure the pipe and fitting are snugly joined.

- Heat the Fitting: Use a torch to evenly heat the fitting until the flux becomes thin and starts to bubble.

- Solder the Joint: Touch the solder to the joint; it should flow into the joint by capillary action.

- Cool and Clean: Allow the joint to cool, then wipe away any excess flux residue.

- Pressure-Test for Leaks: Check for leaks to ensure a secure connection.

Safety Precautions: Always follow safety guidelines, and use lead-free solder for drinking water systems. For detailed techniques and troubleshooting, refer to comprehensive guides.

Quick Steps to Sweat Copper Pipe

To sweat a copper pipe, the installer first measures and cuts the tubing to length, then deburrs the inside and cleans the outside with emery cloth or a wire brush until the metal shines; flux is applied to both pipe and fitting before they are assembled and heated evenly with a torch until solder flows into the joint by capillary action.

The technician secures parts with a prop or clamp, avoiding movement during cooling. Excess solder is wiped gently with a damp cloth. After cooling, joints are inspected for complete fillets and leaks.

Proper ventilation and flame control are maintained throughout the process.

When to Sweat Copper Pipe vs. Use Fittings

When should an installer sweat copper pipe versus using threaded, compression, or push-fit fittings depends on the joint’s permanence, access, system pressure, and material compatibility.

Sweating is preferred for permanent, leak-resistant connections in concealed or high-pressure lines and where thermal cycling occurs.

Compression or threaded fittings suit temporary, accessible, or low-pressure repairs and disassembly needs.

Push-fit fittings excel for quick repairs, tight spaces, or when tools/time are limited, though they may not match soldered longevity under extreme conditions.

Material changes, code requirements, and future serviceability also guide the choice; weigh long-term reliability against convenience and project constraints.

Safety Gear You Must Wear Before Soldering

Why wear protective gear at all? Proper personal protective equipment prevents burns, eye injuries, inhalation of flux fumes, and cuts from sharp tubing.

A solderer should don heat-resistant gloves, safety goggles or a face shield, and long-sleeved, non-synthetic clothing to block sparks and radiant heat.

Respiratory protection—at minimum an N95 or, for poor ventilation, a respirator with organic vapor cartridges—reduces exposure to flux and solder smoke.

Closed-toe, non-slip shoes protect feet from falling tools and hot materials. Ear protection may be warranted for noisy environments.

All gear must fit correctly and remain free of flammable materials.

Set Up a Safe Soldering Work Area

Although soldering can be done in tight spaces, establishing a dedicated, well-organized work area greatly reduces fire risk and improves efficiency. A clear, flat surface away from combustibles is essential; cover it with a fireproof pad or metal tray.

Guarantee good ventilation and position a fan or open window to disperse fumes. Keep a functioning fire extinguisher and a bucket of water or sand nearby.

Arrange parts and flux within reach but separate from heat sources. Maintain bright task lighting and a stable stool or standing mat for comfort.

After work, cool components fully before storing or disposing of scraps.

Tools to Buy for Sweating Copper Pipe

Essential tools make sweating copper pipe safer, faster, and more reliable. A quality propane torch with adjustable flame, compatible tank, and regulator provides consistent heat.

A set of tube cutters sized for common diameters enables clean cuts. A deburring tool and emery cloth guarantee proper joint fit and clean metal. A reliable flame-resistant soldering pad or heat shield and a pair of long-nose pliers protect surrounding materials.

A pipe stand or vise holds work steady. Safety gear—heat-resistant gloves, safety glasses, and a fire extinguisher—completes the kit for competent, efficient soldering tasks.

Materials and Consumables You’ll Need

Before beginning, assemble the right materials and consumables to guarantee clean, watertight sweated joints: copper tubing and fittings matched to the system, lead-free solder or silver-bearing solder appropriate for the application, flux formulated for copper plumbing, and brazing rod or filler when higher-temperature joints are required.

Also include a wire brush or emery cloth for cleaning, pipe cutter and deburring tool, heat-resistant cloth or paste to protect nearby finishes, and a fire extinguisher for safety.

Have plumber’s tape and thread sealant for threaded connections, spare fittings, and a scrap piece of copper for testing solder flow before making final joints.

Choosing the Right Copper Pipe (Type L vs. M vs. K)

With materials and tools ready, selection of the correct copper tubing becomes the next decision because wall thickness affects strength, pressure rating, and suitability for different applications. Type K has the thickest wall for buried or high-pressure lines; Type L suits most residential water systems; Type M is thinner and often used for low-pressure or return lines. Copper grade and local code determine acceptability. Measure pipe OD and verify markings. Consider corrosion risk and ease of soldering; thicker walls tolerate heat variance. Choose accordingly to match system demands and code requirements.

| Type | Typical Use |

|---|---|

| K | Buried, high pressure |

| L | Residential supply |

| M | Low-pressure, return |

| Notes | Check markings and code |

Matching Fittings and Adapters

Selecting the correct fitting size is essential to guarantee a leak-free joint and proper flow.

Attention must also be paid to using the appropriate adapter type when joining dissimilar materials or sizes.

Properly matched fittings and adapters reduce the need for rework and improve long-term system reliability.

Choosing The Right Size

Choosing the correct pipe and fitting sizes is essential to guarantee leak-free joints and proper flow; copper tubing is measured either by nominal (Type K, L, M) outside diameter standards or by actual OD/ID for compression and flare fittings.

Installers must confirm which standard a fitting uses before soldering. Measure pipe OD and wall thickness, identify pipe type stamped on lengths, and match fittings labeled for that system.

Use calipers for accuracy, note if fittings are sweat, compression, or push-fit, and select reducers or couplings sized to the same measurement system.

Proper sizing prevents leaks, pressure loss, and rework.

Using The Correct Adapter

When joining different types or sizes of copper tubing, the installer must match adapters and fittings to the pipe standard and connection type to guarantee a reliable joint.

Adapters convert between sweat, compression, flare, and threaded connections; selecting the correct gender, size, and material prevents leaks and galvanic corrosion.

Changeover fittings suit K, L, or M copper wall thicknesses and must be rated for the system’s pressure and temperature.

When joining copper to dissimilar metals, use dielectric unions.

Verify markings, use proper solder or flux for the fitting type, and test the assembly under pressure to confirm a secure, code-compliant connection.

Measure and Mark Pipe Accurately

Accurate measurements and clear marks are essential before cutting or fitting copper pipe to guarantee joints align and fittings sit flush. The installer measures twice, accounting for insertion depth of fittings and any offsets.

A reliable tape measure and a marker or scribe provide repeatable lines; marks should be made perpendicular to the pipe axis at the exact cut point.

When planning runs, include allowance for elbows, tees, and clearance to walls or fixtures. Transfer measurements to multiple pipes using a simple template when repeats are required.

Confirm measurements against fittings dry-fit to prevent rework before proceeding.

Cutting Copper Pipe Squarely and Cleanly

Begin by securing the pipe firmly in a vise or with a clamp to prevent movement, then use a proper tubing cutter or fine-toothed hacksaw to make the cut. The operator scores evenly, rotates the cutter, and tightens gradually for a square finish. Keep the blade perpendicular and steady; avoid bending or twisting. After cutting, inspect the face for burrs and unevenness (deburring is covered later). Visualize the ideal result: uniform circular edge, flat face, clean end ready for fitting.

| Tool | Action | Goal |

|---|---|---|

| Tubing cutter | Score & rotate | Square cut |

| Hacksaw | Straight stroke | Clean end |

| Vise | Hold steady | No movement |

| Marker | Align cut | Accurate length |

| Eye | Inspect face | Even surface |

Deburr and Sand Pipe Edges Correctly

After cutting, the pipe end must be deburred and lightly sanded to remove sharp edges and guarantee a smooth mating surface.

A deburring tool or round file removes the inner burr; rotate gently until the lip is gone.

Use emery cloth or a fine abrasive pad on the outer edge and the mating area to expose clean bright metal, working circumferentially.

Avoid over-sanding; the goal is smoothness without thinning the wall.

Wipe away filings and dust with a clean rag or brush.

Inspect visually and by touch for any remaining roughness before proceeding to fit the pipe into the fitting.

Why Flux Matters and Which Type to Use

Flux plays a critical role in soldering copper pipes by cleaning oxide from metal surfaces, promoting wetting, and allowing molten solder to flow evenly into the joint.

Flux prevents re‑oxidation during heating and helps reveal faulty joints by improving solder behavior.

For plumbing, use a water‑soluble, non‑acidic paste flux labeled for potable water systems; it cleans effectively and rinses away.

Avoid acid fluxes that corrode copper and sanitary systems.

Rosin flux suits electrical work but isn’t ideal for plumbing.

Choose flux compatible with pipe material and solder alloy, follow manufacturer temperature ratings, and store unopened containers to maintain performance.

How to Apply Flux (Amount and Placement)

Apply a thin, even layer of paste flux to the cleaned surfaces to secure proper wetting and solder flow: coat the outside of the pipe tip and the inside of the fitting just enough to cover the mating surfaces without excess that could squeeze into the bore.

The practitioner guarantees uniform coverage and avoids clumping or gaps. Excess flux is wiped away; insufficient flux risks poor capillary action. Attention to placement preserves flow paths and prevents contamination.

Recommended technique:

- Apply sparingly with a brush around the pipe circumference.

- Brush a light ring inside the fitting.

- Inspect for full but minimal coverage before assembly.

Choose the Right Solder and Torch

When selecting materials for copper pipe joints, the practitioner should match solder alloy and torch type to the pipe diameter, joint clearance, and system application: use lead-free 95/5 or 99/1 tin-silver solders for potable water, choose higher-silver-content alloys for strength on larger pipes, and pair small-diameter work with a pencil-tip torch while reserving a larger, adjustable propane or MAPP gas torch for 1-inch and larger tubing to guarantee adequate, controllable heat.

Flux-compatible rosin-core or solid-core wire is selected by joint temperature and accessibility. Match torch tip size to joint mass, keep regulators adjusted, and stock spare tips and solder diameters.

Pre-Fit and Align the Joint Before Heating

Dry-fit the pipes and fittings to verify seating, alignment, and gap before any heat is introduced. The practitioner inspects joints for burrs and clean surfaces, ensuring a uniform 0.2–0.4 mm capillary gap where applicable. Proper alignment prevents stress and leaks after cooling.

- Ream and deburr the pipe end, then polish the fitting bore to remove contaminants.

- Use a square and level to confirm axial and angular alignment, adjusting support or cut length as needed.

- Temporarily clamp or tape assemblies to maintain position during flux application, avoiding movement that would compromise solder flow.

How to Heat a Copper Joint the Right Way

Several simple steps guarantee the joint reaches the correct temperature without damaging the pipe or fitting.

The plumber positions the torch to heat the fitting first, moving the flame around evenly to warm both parts simultaneously. A steady, controlled flame avoids overheating; broad, sweeping motions distribute heat while avoiding direct, intense focus on one spot.

The workpiece is rotated or the torch moved to maintain uniform temperature. Flux is kept from burning by heating gradually. If nearby components risk heat damage, heat sinks or damp rags are applied.

Once heated appropriately, solder is applied promptly and smoothly.

How to Tell When a Joint Is Hot Enough

How can a plumber quickly and reliably tell that a copper joint has reached the right temperature for soldering? Practical indicators guide the decision without guessing. Visual, tactile, and tool-based cues confirm readiness.

- Observe color and flux: flux liquefies and becomes clear; pipe darkens slightly but not glowing.

- Check flux behavior: when flux thins and flows around the seam, heat is adequate for solder to melt on contact.

- Use a temperature tool: an infrared thermometer reading around 350–400°F (175–205°C) or a temperature stick verifying target range supplies objective confirmation before applying solder.

Apply Solder and Make a Proper Capillary Bond

Feed solder into the heated joint steadily so molten alloy is drawn into the seam by capillary action rather than forced in with heat.

The operator should touch the solder to the junction, not the flame, allowing flow to wick around the fitting evenly.

Rotate the assembly gently if needed to encourage uniform distribution.

Continue feeding until a complete fillet forms around the bore, indicating full penetration.

Avoid excessive solder that can create drips or restrict flow.

If gaps appear, reheat briefly and add a little more solder.

Maintain steady hand control and steady heat to guarantee a reliable, leak-resistant capillary bond.

Cool, Clean, and Finish the Joint

Once the solder has wicked fully around the joint and a continuous fillet is visible, the piece should be allowed to cool naturally without disturbing the connection.

Cooling prevents cold joints and preserves capillary integrity. After cooling, flux residue must be removed promptly to stop corrosion. Clean with a damp cloth or brush, then inspect visually and by touch for smoothness and full coverage.

Finally, finish the joint to protect and present it professionally:

- Remove flux with warm water and a brush; dry thoroughly.

- File or de-burr any sharp solder edges lightly.

- Apply a corrosion-inhibiting compound or paint as needed.

Pressure-Test a Soldered Joint for Leaks

Before reintroducing the system to full service, the soldered joint should be pressure-tested to confirm a leak-free seal and to reveal any defects that visual inspection may miss.

Isolate the repaired section, cap or close valves, and pressurize with water or air at the system’s normal operating pressure or slightly above, following local codes.

Monitor the joint for at least several minutes, watching for drips, wetness, or pressure loss on gauges.

If a leak appears, depressurize, dry, and reheat to reflow solder or replace the fitting.

Only return the system to service after a sustained, stable pressure reading.

Sweat Copper Pipe in Tight or Hard-to-Reach Spaces

When sweating copper in tight or hard-to-reach spaces, the technician relies on access and visibility tricks such as mirror placement, inspection cameras, or angled fittings to position the joint.

Precise heat control techniques—including small-tipped torches, flame shields, and intermittent heating—prevent overheating nearby materials and guarantee even solder flow.

Combining improved sightlines with careful temperature management reduces rework and improves joint reliability.

Access And Visibility Tricks

How can a solder joint be reliably made in cramped, poorly lit locations without sacrificing safety or quality? The technician prepares by improving access and sightlines, choosing compact tools, and securing the work area.

Lighting, positioning, and stabilization are emphasized to prevent movement and burns. Practical measures include mirror or camera aids, flush fittings, and temporary brackets to hold fittings steady. Minimal prep reduces rework and exposure.

- Use headlamp or flexible LED and inspection mirror.

- Employ right-angle or mini torch and long-nose clamp.

- Stabilize pipes with straps, blocks, or quick-release braces.

Heat Control Techniques

Although confined spaces limit maneuverability, precise heat control remains the key to reliable sweat joints. The technician focuses on directing flame, managing dwell time, and preventing heat migration to adjacent components.

In tight areas, use a small pencil torch or micro-tip to concentrate heat on the fitting, heating the joint evenly while avoiding prolonged exposure. Employ heat sinks or wet cloths to shield nearby fittings and solder joints.

Rotate pipe or reposition flame incrementally to distribute heat. Monitor temperature by touch or heat-indicating flux. Quench excess heat quickly to protect seals and insulation, ensuring a clean, leak-free connection.

Joining Different Copper Sizes and Adapters

Because plumbing systems often combine pipes of different diameters and thread types, joining dissimilar copper sizes and adapters requires selecting compatible fittings and preparing each connection carefully.

Adapters, reducers, and couplings must match O.D. or use properly sized compression or sweat fittings. Surfaces are cleaned, fluxed, and trial-fit to guarantee full seating and correct alignment before heating. Excessive gap or misfit prevents capillary action and weak joints.

Use appropriate flux for alloy and clean solder type. After soldering, joints are cooled, inspected for gaps, and pressure-tested to verify integrity.

- Choose correct adapter type and size.

- Deburr and clean mating surfaces.

- Trial-fit, flux, solder, then test.

Sweating Copper to Brass and Threaded Fittings

Sweating copper to brass and threaded fittings requires attention to material differences and proper preparation to guarantee a leak-free joint.

The brass fitting should be cleaned and de-greased; internal threads must be protected from flux and solder by using fitting tape or removing threads where soldering will occur.

Flux selection matters—use an appropriate flux for joining dissimilar metals.

Apply heat evenly to the copper, not the brass, allowing solder to draw into the joint by capillary action.

After cooling, remove flux residue to prevent corrosion.

Threaded joints meant to remain removable should not be soldered; use proper thread sealant instead.

Repairing a Leaking Soldered Joint (Without Replacing Pipe)

When a soldered joint begins to leak, the first step is to locate the exact source of the leak and shut off the water.

The joint should be cleaned of corrosion and old solder until bright copper is exposed to guarantee proper adhesion.

Finally, the joint is reheated and fresh solder applied to reseal the connection, then inspected for a watertight finish.

Locate The Leak

How can a precise leak location be determined on a soldered copper joint without removing pipe sections? A systematic, noninvasive inspection isolates the breach quickly. Visual cues, feel, and minor tests guide the process.

- Inspect: dry the joint, use a flashlight to find pinholes, cracks, or uneven solder beads; watch for tiny wet spots or corrosion.

- Touch: run a gloved finger along the seam to detect moisture trails; feel for temperature differences with brief cold water flow.

- Test: apply a soapy water solution while repressurizing briefly; bubbles reveal escaping air or water at the exact defect.

Prepare And Clean

Before any repair work begins, the joint must be fully prepared: turn off and drain the water, dry the area, and clear away old solder, flux residue, corrosion, and paint so the surfaces are bright and clean.

Using emery cloth or a wire brush, remove all oxidation from both the pipe and fitting until a uniform, shiny copper appears.

Scrape out old solder from the seam with a reamer or small file, and clean crevices with a pick.

Wipe surfaces with a lint-free rag and apply a small amount of flux to the cleaned joint immediately before reheating.

Reheat And Reseal

Apply heat evenly to the prepared joint, focusing the flame on the fitting rather than the pipe until the flux begins to sizzle and the metal reaches soldering temperature; then touch the solder to the joint, allowing it to flow into the seam by capillary action.

Remove heat, and let the joint cool undisturbed to form a reliable seal. The technician inspects the cooled joint for full fillet and continuity, wiping residual flux and testing with water pressure.

If leaks persist, repeat controlled reheating and add solder sparingly.

Steps:

- Clean and flux the leak area.

- Reheat and feed solder.

- Cool and pressure-test.

Common Soldering Mistakes and How to Avoid Them

Although soldering copper pipes is straightforward with practice, common mistakes still lead to leaks, weak joints, and rework.

Beginners often skip proper cleaning; flux and solder won’t bond to dirt, oil, or oxidation. Overheating flux burns away its activity, so heat gradually and move the flame evenly.

Applying solder to the flame instead of the joint hides poor capillary action; feed solder to the heated seam until it draws in. Using the wrong solder or flux for potable water risks contamination.

Inadequate support causes movement during cooling, weakening joints. Inspect, test, and correct seams before restoring service.

When to Choose Push-Fit Fittings Instead

When time is limited or a project requires quick completion, push-fit fittings offer a fast alternative to soldering.

They are especially useful when the installer lacks a torch or other specialized tools.

The section will outline scenarios where speed and minimal equipment make push-fit the preferable choice.

When Speed Matters

Need a job done quickly and reliably? When speed matters, push-fit fittings offer a fast, secure alternative to sweating copper: no torch, no flux, no wait. They suit repairs, tight timelines, and situations where minimizing downtime is essential.

- Rapid installation — simply cut, deburr, and push; connection forms in seconds.

- Temporary or emergency use — ideal for immediate fixes before planned soldered work.

- Accessibility and vibration tolerance — useful in cramped or moving environments where soldering is impractical.

However, for long-term certainty on high-pressure systems, soldered joints often remain the preferred professional choice.

Limited Tools Available

Work with what’s on hand: push-fit fittings are the practical choice when tools are limited, eliminating the need for a torch, solder, flux, or a full plumbing toolkit.

They allow reliable connections with only a cutter and deburring tool, reducing setup time and safety concerns. For renters, tight spaces, or quick emergency repairs, push-fit minimizes skill requirements and permits immediate water restoration.

Limitations include higher material cost and potential unsightliness in finished installations; long-term reliability depends on manufacturer quality and correct installation.

When tools, experience, or time are lacking, push-fit fittings offer a safe, efficient alternative to sweating copper.

Maintain and Extend the Life of Soldered Copper Plumbing

Regular inspection and simple preventive measures greatly extend the service life of soldered copper plumbing by catching minor issues before they escalate.

Routine visual checks, gentle cleaning, and prompt leak repairs preserve joints and reduce corrosion risk. Proper water chemistry and avoiding dissimilar metals limit galvanic action. Insulate exposed runs to prevent freezing and minimize thermal cycling stress. Documenting work and using quality flux and solder during repairs guarantees durable bonds.

- Inspect: monthly for leaks, corrosion, loose supports.

- Protect: insulate, control water pH, separate metals with dielectric fittings.

- Repair: address solder flaws immediately with proper materials.

Simple Practice Joints to Build Confidence

The section introduces three starter joints to build practical soldering skills: basic butt joints for straight connections, tee joints for branch lines, and corner/offset joints for changes in direction.

Each practice setup focuses on proper fit, even heating, and controlled solder flow.

Clear, repeated practice on these simple configurations helps develop confidence before tackling live plumbing.

Basic Butt Joint Practice

Begin by assembling short lengths of copper pipe and matching fittings to practice basic butt joints; these simple repetitions build muscle memory and reveal common alignment and heating errors without risking a finished installation.

The practitioner focuses on preparation: clean cuts, deburring, and flux application. Controlled heating concentrates on the joint, drawing solder into the seam by capillary action. Immediate inspection for uniform fillets and voids trains the eye.

Repeatable exercises refine torch distance and travel speed.

- Clean and flux thoroughly.

- Heat evenly, touch solder to the joint.

- Inspect and file mistakes for learning.

Tee Joint Techniques

After practicing butt joints to master alignment and heating control, the learner advances to tee joints to build confidence with three-way connections and flow paths.

The exercise emphasizes clean cuts, proper deburring, and accurate fitting of the branch into the run. Flux application should be even, avoiding excess that could clog the bore.

Heat the joint evenly, watching solder draw into both intersections; begin at the run to encourage capillary action toward the branch.

Practice with varied pipe sizes and orientations to understand heat distribution. Inspect each practice tee for complete fillets and leak-free performance before progressing.

Corner And Offset Joints

Corner and offset joints introduce learners to non-collinear alignments where pipes meet at angles or require a stepped connection, reinforcing measurement, cutting, and fitting skills.

Practice emphasizes accurate mitering, consistent gaps for capillary action, and secure support to prevent movement during heating. Common exercises build confidence before live systems are attempted.

- Measure and mark twice, cut with a tube cutter, deburr, and dry-fit to verify alignment.

- Apply flux evenly, assemble with correct gap, heat progressively, and feed solder until fillets form.

- Inspect joints for continuity, clean residue, and pressure-test for leaks.

Cost, Time Estimate, and When to Call a Licensed Plumber

When estimating a copper pipe soldering job, consider materials, labor, and unforeseen repairs to produce a realistic cost and time window.

Typical DIY materials—flux, solder, torch, fittings—run $20–$80 per small project; replacement pipe and specialty fittings raise costs.

A straightforward joint takes 15–45 minutes; allow extra time for cutting, cleaning, evacuating water, and testing.

Complex runs or multiple joints multiply labor.

Call a licensed plumber when leaks persist, when work involves mains, gas lines, burst pipes, building-code permits, inaccessible sections, or soldering beyond one’s skill.

Professional diagnosis prevents property damage and guarantees code compliance.

Conclusion

Like a steady hand guiding molten silver through a river of copper, mastering the sweat joint turns nervous fumbling into fluent craft. The beginner, armed with safety gear, clear steps, and a few practice joints, can weld small household leaks into lasting seams; yet the horizon still sometimes demands a licensed pro. With patience as torchlight and good tools as compass, soldered plumbing becomes durable art rather than fleeting patchwork.