How to Attach PVC Pipe to Wood: Easy DIY Guide & Tips

To securely attach PVC pipe to wood, use cushioned pipe straps or U-bolts with corrosion-resistant screws, spaced every 3–4 feet for ½–1″ pipe, and closer for larger sizes. For a more permanent connection, solvent-weld PVC with primer or apply polyurethane/epoxy adhesives on sanded and cleaned surfaces, clamping until cured. Remember to pre-drill the wood and avoid over-tightening to prevent damage. Additionally, seal outdoor penetrations and allow for thermal movement.

Key Takeaways:

- Use cushioned strap or U-bolt with screws.

- Space attachments every 3–4 feet.

- For permanent joints, use solvent weld or adhesive.

- Pre-drill and avoid over-tightening.

- Seal outdoor penetrations for durability.

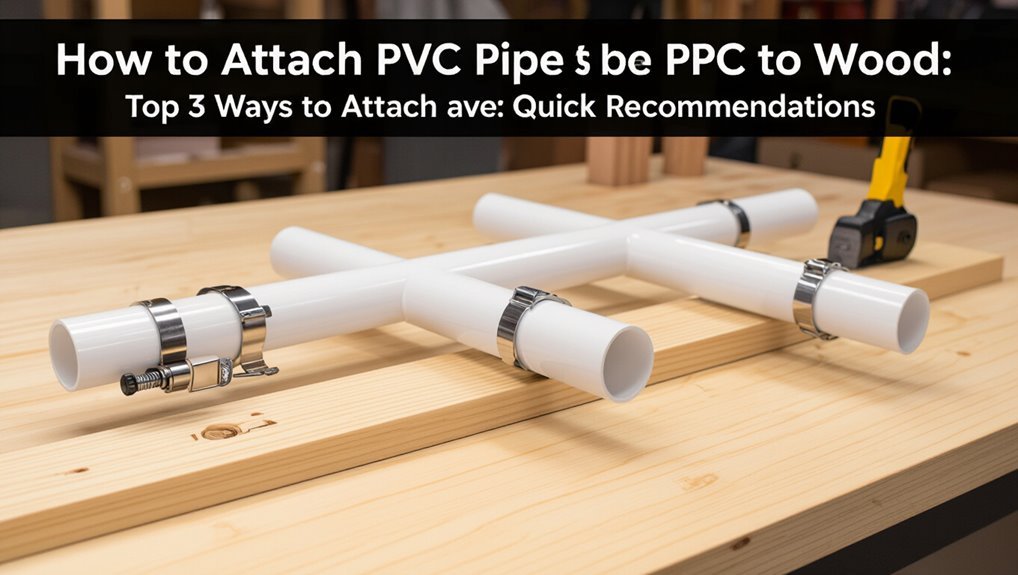

Top 3 Ways to Attach PVC to Wood : Quick Recommendations

For quick, reliable results when fastening PVC to wood, three methods stand out: mechanical fastening with straps or brackets, adhesive bonding using PVC-specific cements or structural epoxies, and using threaded inserts or flanges for removable connections.

Mechanical straps provide immediate support, resist shear, and suit exposed runs; choose stainless or galvanized hardware and predrill to prevent wood splitting.

Adhesives offer clean lines and distributed load but require surface preparation, correct solvent cement or epoxy selection, and clamping during cure.

Threaded inserts or flanges permit disassembly and precise alignment; install into wood with proper pilot holes and torque limits to avoid damage.

Which Method Fits Your Project: Clamp, Screw, or Adhesive?

The section compares clamp mounting options, screw fastening tips, and adhesive bonding methods to help choose the right approach for a given project.

Each method’s strengths and limitations are summarized with attention to load, permanence, and ease of installation.

Practical considerations such as pipe size, environmental exposure, and surface preparation guide the recommended choice.

Clamp Mounting Options

Among common methods for fastening PVC to wood, clamp mounting offers a balance of strength and removability, making it suitable for projects that may require adjustment or replacement.

Clamps come in U-shaped pipe straps, cushioned cushy-lined clamps, and adjustable hinge clamps; selection depends on pipe diameter, load, vibration, and aesthetics.

Metal straps provide rigidity for structural runs, while plastic or rubber-lined clamps protect against abrasion and reduce noise.

Proper spacing, typically every 3–6 feet for horizontal runs and closer for small-diameter lines, prevents sagging.

Installation requires marking, pilot drilling for straps that use screws, and ensuring clamps sit square to the pipe.

Screw Fastening Tips

When a more permanent attachment is desired than clamps provide, screw fastening offers direct anchoring of PVC to wood with minimal hardware profile.

Careful pilot holes prevent splitting and reduce stress on the pipe. Use corrosion-resistant screws sized to bite the wood without crushing the PVC; countersinking or shallow recesses keep heads flush.

For thin-walled pipe, distribute fasteners to avoid deformation and allow slight movement for thermal expansion. Consider using small fender washers or short metal straps where pipe strength is marginal.

- Pilot holes slightly smaller than screw core

- Use stainless or coated screws

- Space fasteners evenly

- Allow thermal movement

Adhesive Bonding Methods

For projects requiring a lower-profile, permanent hold without penetrating the pipe, adhesive bonding offers several viable options tailored to PVC and wood. The section compares solvent welds, construction adhesives, and epoxies: solvent cement chemically fuses PVC but needs a compatible primer and dry wood; polyurethane or hybrid construction adhesives bond mixed substrates with gap-filling strength; two-part epoxy yields high shear strength for stressed joints. Surface preparation, clamping until cure, and matching working time to application are critical. Choose based on load, environment, and service temperature for reliable performance.

| Method | Strength | Best Use |

|---|---|---|

| Solvent weld | High | PVC-to-PVC or PVC-to-prepped wood |

| Construction adhesive | Medium-High | Mixed materials, gaps |

| Two-part epoxy | Very High | Structural, stressed joints |

Tools & Materials You’ll Need

To attach PVC pipe to wood reliably, a concise set of tools and materials is required: PVC pipe and appropriate fittings, a PVC cutter or fine-tooth saw, primer and solvent cement for any solvent-weld joints, pipe hangers or straps sized to the pipe, wood screws or lag bolts, a drill with bits for pilot holes, a level and tape measure, and appropriate safety gear (gloves and eye protection).

Additional useful items include wood anchors for hollow substrates, cushioning tape to reduce vibration, and a marker for alignment.

Proper selection guarantees secure, durable fastening without overengineering.

- Choose correct hanger size and type.

- Select screw/bolt grade.

- Use primer where needed.

- Confirm measurements before drilling.

Prep PVC and Wood for a Strong Bond

Prepare both surfaces deliberately: clean the PVC with a solvent wipe or denatured alcohol to remove oils and dirt, and sand any glossy areas lightly with fine-grit sandpaper to promote adhesion. Dry both pieces fully.

On the wood, remove loose fibers and dust, then sand the contact area smooth for consistent glue spread. If using adhesive, apply manufacturer-recommended primer to PVC and a thin, even bead of solvent cement or construction adhesive to one surface.

Clamp or weight the joint as instructed, avoiding overpressure that squeezes out adhesive. Allow full cure time before stressing the connection for reliable strength and longevity.

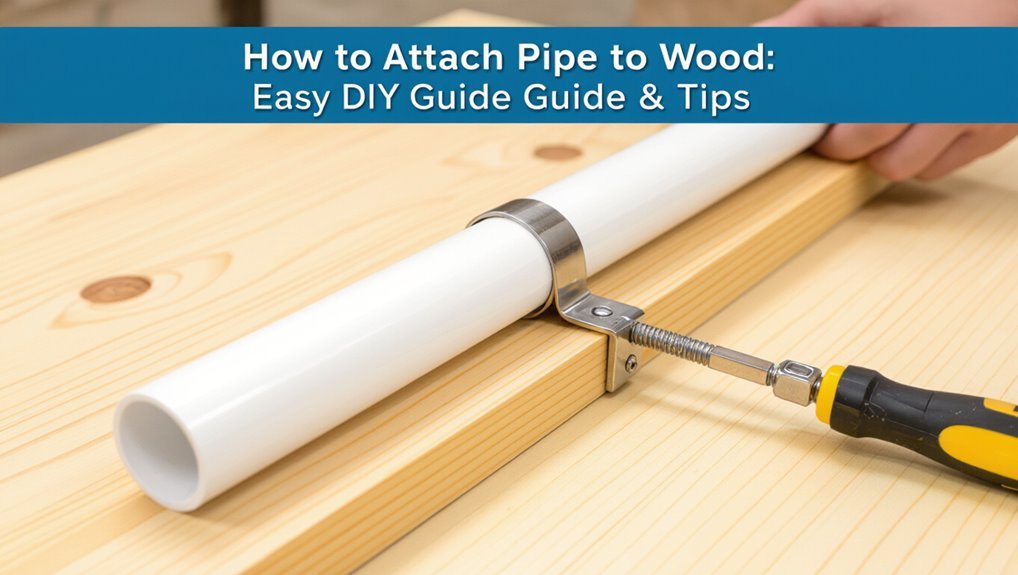

How to Use Pipe Straps and Clamps on Wood

Selection of an appropriately sized and material-matched pipe strap is essential for secure PVC-to-wood attachment.

Proper fastening technique—including using the right screw length, pre-drilling pilot holes, and spacing straps at manufacturer-recommended intervals—prevents movement and wood splitting.

Attention to strap type and correct installation guarantees long-term support and alignment of the piping run.

Choosing The Right Strap

Choosing the right strap is essential for secure, long-lasting PVC-to-wood connections: the proper size, material, and mounting style prevent sagging and protect both pipe and substrate. Selection depends on pipe diameter, exposure conditions, and load. Metal straps suit outdoor or high-heat areas; plastic or nylon straps resist corrosion and avoid scratching.

Cushioning inserts reduce vibration and wear. Consider strap width and hole spacing to match wood grain and avoid splitting.

- Match internal diameter and allow slight movement.

- Choose corrosion-resistant material for environment.

- Use cushioned straps where vibration occurs.

- Select hole spacing compatible with stud layout.

Proper Fastening Techniques

Install pipe straps and clamps with consistent spacing and proper fastener choice to guarantee secure, load-bearing PVC-to-wood connections without introducing stress points.

Fasteners should match wood type and load: use corrosion-resistant screws for exterior installations and wood screws or lag bolts for heavy runs. Pre-drill pilot holes to prevent splitting and to align straps squarely.

Space supports according to pipe diameter and application — typically 3–4 feet for horizontal runs, closer for vertical or long spans.

Allow slight lateral movement for thermal expansion by not over-tightening; use cushioned or rubber-lined clamps where vibration or abrasion is a concern.

Screwing PVC to Wood: Saddle Brackets & Anchors

When fastening PVC pipe to wood, saddle brackets and anchors provide secure, low-profile support that resists lateral movement and vibration. Saddle brackets cradle pipe, distribute load, and allow thermal expansion. Select corrosion-resistant metal or UV-stable plastic brackets sized to pipe OD. Pre-drill holes in wood to prevent splitting; use screws long enough to engage framing.

For hollow-wall or masonry substrate, use appropriate anchors—toggle, sleeve, or masonry anchors—installed per manufacturer instructions. Space supports according to pipe diameter and application (drain, supply, or conduit). Properly torqued fasteners prevent creep and maintain alignment over time.

- Choose correct bracket size

- Pre-drill pilot holes

- Use suitable anchors

- Space supports appropriately

When to Use Construction Adhesive or Epoxy on PVC

Construction adhesive is suitable for light, non-structural PVC attachments where shear and tensile loads are minimal.

Epoxy is recommended for joints that will bear significant stress, impact, or where a gap-filling, load-bearing bond is required.

In both cases, surfaces must be cleaned, sanded or abraded, and degreased to guarantee proper adhesion.

When Adhesive Is Appropriate

In specific situations, adhesive offers a practical alternative to mechanical fasteners for joining PVC to wood—particularly where loads are light, access for screws is limited, or a flush surface is required. Adhesive bonding suits temporary installs, cosmetic mounts, and indoor, dry environments. Proper surface preparation—cleaning, roughening, and priming—ensures reliable adhesion. Choose construction adhesive for general-purpose joints; reserve specialized products when chemical compatibility matters. Avoid relying on adhesives for dynamic, high-stress, or outdoor wet applications.

- Lightweight conduit runs

- Concealed cosmetic attachments

- Limited access or thin wood substrates

- Vibration-free, low-load fixtures

Epoxy For High Stress

Reach for epoxy when joints must withstand sustained loads, impact, or outdoor exposure that exceed the capabilities of standard construction adhesives.

Epoxy bonds offer higher tensile and shear strength, better gap-filling, and improved resistance to moisture and temperature cycling.

Use two-part marine-grade or structural epoxy for load-bearing pipe clamps, cantilevered connections, or where vibration occurs.

Construction adhesive suffices for light-duty, indoor, non-structural attachments.

Consider cure time, working life, and compatibility with PVC; some epoxies require primer or specific formulations for polyvinyl surfaces.

When longevity and safety matter, epoxy provides a more reliable permanent connection than typical adhesives.

Surface Preparation Steps

When preparing PVC and wood for adhesive bonding, assess substrate condition and choose a compatible adhesive—construction adhesive for low-stress, indoor joints and epoxy for high-stress, outdoor, or vibration-prone connections.

Surfaces must be clean, dry, and free of oils, paint, or loose fibers. Lightly abrade PVC with fine sandpaper to increase mechanical grip; wipe with isopropyl alcohol. For wood, remove dust and ensure flat mating faces.

Follow adhesive manufacturer cure times and clamp as recommended.

- Clean with solvent and let fully dry.

- Sand PVC and brush away debris.

- Make certain wood is solid and sealed if porous.

- Apply adhesive evenly and clamp.

Drilling Tips: Hole Sizes, Pilot Screws, Avoiding Splits

Typically, installers start by matching drill-bit size to the fastener and the PVC wall thickness to guarantee a snug but not overly tight fit; pilot holes sized to the screw’s core shank prevent wood splitting and allow the threads to bite properly, while clearance holes for the screw’s outer thread may be used through PVC to avoid compressing the pipe.

Select drill bits slightly smaller than the wood screw’s root diameter for hardwood, matching or equal for softwood. Use a countersink for flush seating.

Pre-drill through PVC with a bit equal to the screw’s outer diameter. Work slowly near edges and back up brittle pieces.

Hangers and Suspension: Installing PVC on Runs

The section examines appropriate hanger types for PVC, from cushioned straps to rigid clamps, and their suitability for different pipe diameters and environments.

It also outlines recommended spacing intervals and factors—such as thermal expansion, load, and vertical runs—that influence support frequency.

Practical guidance on anchoring to wood while allowing movement preventative stress is introduced.

Choosing Hanger Types

Several common hanger types serve distinct needs for PVC runs, and selecting among them depends on pipe size, load, spacing, and environment. Choice balances security, vibration control, and ease of installation.

Metal saddle clamps offer durability for heavy or outdoor lines; plastic cushioned clamps prevent abrasion and suit indoor plumbing; strap hangers provide flexibility for odd shapes and thermal movement; beam clamps attach to structural members without drilling. Consider chemical exposure, temperature, and whether insulation is required.

Properly matched hangers reduce stress on joints and maintain alignment, but exact spacing and support practices are addressed in the next section.

- Metal saddle clamps

- Plastic cushioned clamps

- Strap hangers

- Beam clamps

Spacing And Support

When supported at proper intervals, PVC runs resist sagging, joint stress, and water hammer effects while maintaining alignment for fittings and flow. The installer measures span, selects hangers rated for temperature and load, and secures supports to wood framing. Horizontal 1–2″ pipe usually needs supports every 3–4 feet; larger diameters require closer spacing. Use cushioned clamps to prevent chafing and allow thermal movement with split hangers or straps. For long vertical drops, sway bracing and intermediate supports reduce vibration. Periodic inspection guarantees fasteners remain tight and material degradation is caught early.

| Pipe Size | Support Spacing |

|---|---|

| 1/2″ | 3–4 ft |

| 1″ | 3 ft |

| 2″ | 2–3 ft |

Weatherproof Outdoor PVC-to-Wood Connections

How can outdoor PVC-to-wood connections resist moisture, temperature swings, and UV exposure over time? Effective weatherproofing uses materials and methods that prevent water intrusion, allow movement, and block sunlight degradation.

Proper sealants, compatible fasteners, and protective finishes extend service life while minimizing stress on joints. Regular inspection and maintenance catch failures early.

- Use exterior-grade silicone or polyurethane sealant at pipe-to-wood interfaces.

- Install neoprene or EPDM gaskets between PVC fittings and wood to seal gaps.

- Select stainless or hot-dip galvanized fasteners to resist corrosion.

- Apply UV-resistant paint or wrap exposed PVC sections for added protection.

Attaching PVC to Treated Lumber and Cedar: Tips

Having covered weatherproofing strategies for outdoor PVC-to-wood connections, attention now shifts to the particular challenges posed by treated lumber and cedar.

Treated lumber contains chemicals that can corrode some metal fasteners; use stainless steel or hot-dip galvanized screws and straps rated for preservative-treated wood.

Cedar is dimensionally stable but contains natural oils that may inhibit some adhesives; prefer mechanical fasteners or adhesives labeled safe for cedar.

Pre-drill holes to prevent splitting and allow for expansion.

Seal fastener penetrations with exterior-grade sealant to resist moisture.

Consider isolating PVC with non-reactive washers or sleeves where direct contact may cause staining or degradation.

Removable Mounts for Temporary Setups

For temporary installations, removable mounts offer a balance of secure support and easy disassembly, allowing PVC assemblies to be attached to wood without permanent alteration.

Removable options include clamps with rubber liners, magnetic mounts (for ferrous backings), hook-and-loop straps with mounting plates, and quick-release brackets. They protect pipe finish, minimize wood damage, and permit repositioning.

Installation emphasizes firm seating, even pressure, and corrosion-resistant hardware. Users should select mounts sized for pipe diameter and intended duration, verify stability before use, and remove mounts promptly when no longer needed to prevent prolonged compression or weathering effects.

- Rubber-lined clamps

- Magnetic bases

- Hook-and-loop plates

- Quick-release brackets

Load Limits & Recommended Spacing for Straps/Hangers

When using removable mounts, attention must turn to the load limits and spacing of straps and hangers to guarantee safe support without overstressing the fasteners or the wood substrate.

Specify pipe diameter and estimated contents weight; lighter 1/2–1″ lines often permit 3–4 ft spacing, while larger or pressurized lines need closer supports, typically 2–3 ft.

Use straps rated for the pipe material and environment; consult manufacturer load ratings and apply a safety factor of 2–3.

For horizontal runs, support at ends and midspan.

Increase density near bends, tees, or where vibration and thermal movement concentrate forces.

Common Mistakes That Weaken PVC-to-Wood Joints

In attaching PVC to wood, several recurring errors undermine joint strength and longevity. Common mistakes include improper adhesive use, misaligned fasteners, insufficient support, and neglecting surface prep. These reduce bond integrity and invite failure under load or weather.

- Using wrong cement or skipping primer, preventing chemical fusion.

- Driving screws too close to the pipe, causing cracks or deformation.

- Relying on widely spaced or single-point supports, increasing stress at joints.

- Failing to clean or sand mating surfaces, leaving dust, oil, or paint that blocks adhesion.

Avoiding these preserves attachment durability and reduces maintenance.

3 Mini Projects: Railing, Irrigation, Conduit (Step‑by‑Step)

Beginning with simple, well-planned projects helps illustrate practical ways to attach PVC to wood: a balcony handrail, a garden irrigation manifold, and a protected electrical conduit each require different fasteners, adhesives, and layout considerations. The handrail uses straps and epoxy for load points; the manifold favors brackets and silicone for water seals; the conduit needs clamps and proper spacing for codes. Each step emphasizes measurement, pilot holes, and corrosion-resistant hardware. Fasten points are staggered to reduce stress. Finish with testing and gentle load or pressure checks before regular use.

| Project | Key Attachment |

|---|---|

| Handrail | Straps + epoxy |

| Manifold | Brackets + silicone |

| Conduit | Clamps + spacing |

| All | Pilot holes |

Troubleshooting: Loose Pipe, Leaks, and Noisy Runs

Troubleshooting loose pipe, leaks, and noisy runs requires a systematic checklist that isolates mounting, sealing, and alignment issues.

One inspection step examines fastener spacing and degraded clamps; tighten or replace with cushioned supports.

Another step evaluates joints for solvent-weld defects or inadequate primer; reassemble or apply appropriate sealant.

Vibrations suggest poor alignment or insufficient expansion space; add hangers or looped runs and use rubber isolators.

For hidden leaks, monitor pressure and dye-test suspect sections, replacing compromised segments.

- Check supports and spacing.

- Verify joint bonds and seals.

- Correct alignment and allow expansion.

- Pressure-test and replace damaged pipe.

Conclusion

Like a gardener tying vines to a trellis, securing PVC to wood shapes a structure that endures wind and seasons. Whether clipped with a strap, anchored with a screw, or bonded with adhesive, each method threads purpose through timber and plastic. With proper prep and spacing, joints hold firm; with care, projects from railings to irrigation sing silent, steady songs. Small mistakes loosen the tune, but thoughtful technique keeps systems rooted and reliable.