How a Water Pipe Works: Simple Guide to Flow, Pressure & Parts

A water pipe functions by transporting water through a system that converts source pressure and elevation into flow, while accounting for pressure losses along the way. Here are the key takeaways:

- Flow Rate Determinants: The flow rate is primarily influenced by the pressure difference and the system’s resistance, which includes factors like pipe diameter, length, roughness, and the presence of fittings and fixtures.

- Valves and Regulators: These components are essential for shaping and isolating water flows within the system.

- Pumps: They are used to boost pressure when natural forces like gravity or mains pressure are inadequate.

- Issues Affecting Flow: Leaks and clogs can significantly reduce flow and lead to drops in pressure.

For more detailed explanations of the components, causes of issues, and simple troubleshooting tips, continue reading.

Quick Answer: What Controls Water Flow and Pressure

Although valves and mains pressure set the basic conditions, water flow and pressure in a pipe are governed by a combination of factors: supply pressure from the source, pipe diameter and length, internal roughness, fittings and valves that create resistance, and the demand downstream.

The source defines available head; larger diameter and shorter runs reduce friction losses; smoother interiors sustain higher velocities with less drop. Each bend, valve, or restriction adds localized loss.

Downstream demand—flow rate required by fixtures or appliances—determines how pressure is distributed and how quickly supply is depleted.

System balance relies on matching capacity to demand and minimizing avoidable resistance.

How Water Flow and Pressure Actually Relate

Building on the factors that set supply and resistance, the relationship between flow and pressure can be described quantitatively: pressure provides the energy that drives flow, while flow consumes that energy through friction and fittings, causing pressure to drop along the pipe.

Flow rate depends on pressure difference between two points and the system’s hydraulic resistance; higher pressure difference yields higher flow if resistance is constant.

Conversely, increasing flow raises velocity and frictional losses, reducing downstream pressure.

Pipe diameter, length, roughness and fittings set resistance; flow and pressure adjust until energy supplied equals energy dissipated by those losses.

What Creates Household Water-Pipe Pressure

Household water-pipe pressure originates from a few primary factors that control the force pushing water through pipes.

Elevation of the water source establishes static pressure by gravity, while municipal or booster pumps add pressure where elevation is insufficient.

Pressure-regulating valves then adjust and stabilize that pressure for safe, consistent delivery to fixtures.

Water Source Elevation

Water source elevation determines the static pressure available in a water distribution system because gravity converts the vertical difference between the water surface and the point of use into hydrostatic pressure.

The elevation of reservoirs, tanks, or natural sources sets baseline pressure; higher head yields greater pressure without mechanical aid. Terrain and storage siting influence achievable head and zone boundaries.

Pipe friction and fittings reduce delivered pressure but do not change the head provided by elevation.

- Head calculation: pressure (kPa) ≈ 9.81 × elevation difference (m).

- Zoning: different elevations create pressure zones requiring control.

- Safety: excessive head risks pipe stress and leaks.

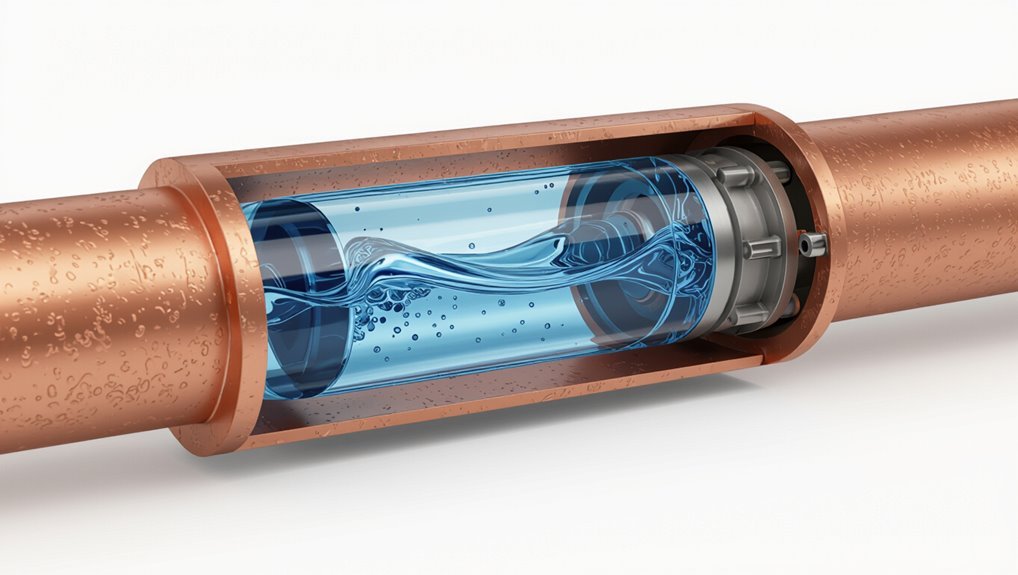

Pumping Mechanisms

Several mechanisms create the pressure that moves water through domestic pipes, most commonly centrifugal pumps driven by electric motors and gravity-fed systems augmented by pressurized storage tanks.

These devices convert mechanical energy into fluid pressure, overcoming static head and frictional losses to deliver flow at fixtures. Centrifugal pumps impart velocity via an impeller, converting it to pressure in the volute. Positive displacement pumps deliver fixed volume per cycle for higher pressures.

Booster pumps increase municipal supply when demand exceeds static pressure. Well systems use submersible pumps and pressure tanks to reduce cycling.

Proper pump sizing matches required flow and total dynamic head.

Pressure-Regulating Valves

Pressure-regulating valves (PRVs) maintain stable line pressure by automatically throttling flow when incoming municipal or pump-supplied pressure exceeds a setpoint.

They protect fixtures and piping from overpressure, reduce water hammer risk, and improve system longevity. Installed near the service entry, PRVs employ a spring-loaded diaphragm to sense downstream pressure and adjust an internal seat.

Periodic adjustment or replacement is necessary when wear or debris alters performance. Properly sized PRVs balance adequate flow with target domestic pressures, typically 50–60 psi, ensuring user comfort while preventing unnecessary stress on valves and joints.

- Sensing mechanism: diaphragm and spring.

- Installation: service entry placement.

- Maintenance: adjustment, cleaning, replacement.

Water-Pipe Parts and Their Functions

The section outlines the main components of a household water-pipe system, including pipes, fittings, valves, and fixtures.

It explains how each part contributes to flow, pressure control, and system integrity.

Special attention is given to the roles of valves and joints in regulating water movement and preventing leaks.

Main Components Overview

A water-distribution system consists of a handful of primary components—source, pump, pipes, valves, fittings, meters, and fixtures—each performing a distinct mechanical or control function to move, direct, measure, and deliver potable water.

The overview identifies roles: sources store or collect; pumps provide energy; pipes transport; meters quantify; fixtures deliver use.

Materials, sizes, and arrangement determine capacity, pressure loss, and maintenance needs. Accessibility and isolation points enable repair.

Corrosion resistance, joint types, and support systems affect longevity. Controls and monitoring integrate with system hydraulics to maintain reliable service.

- Source, pump, pipe

- Metering and fixtures

- Materials and supports

Valve And Joint Roles

Valves and joints form the control and connection network within a water-distribution system: valves regulate flow, isolate sections for maintenance, and enable pressure or direction changes, while joints and fittings provide sealed connections between pipe segments, accommodate movement, and prevent leaks.

Valves vary—gate, ball, globe, check—each offering specific control, throttling, or nonreturn functions; selection balances flow characteristics, response speed, and maintenance access.

Joints include threaded, welded, flanged, and flexible couplings; proper selection absorbs thermal expansion, ground movement, and vibration.

Correct installation, routine inspection, and material compatibility are essential to maintain system integrity and minimize failures.

How Pipe Size, Shape, and Material Affect Flow

Pipe diameter, cross-sectional shape, and construction material directly determine how water moves through a system: larger diameters reduce velocity and friction losses for a given flow rate, noncircular shapes alter velocity profiles and can increase turbulence, and materials affect surface roughness and consequently energy dissipation.

Flow capacity, pressure drop, and susceptibility to turbulence follow from those parameters, influencing pump selection and pipe routing. Engineers balance cost, space, and hydraulic performance when specifying pipe geometry and material to meet design targets and longevity.

- Diameter: governs Reynolds number and head loss.

- Shape: affects boundary layers and mixing.

- Material: sets roughness and corrosion behavior.

Valves, Joints, and Fittings: How They Control Flow

Although often unseen, valves, joints, and fittings are the deliberate control points that regulate flow, isolate sections, and adapt piping geometry to system needs.

Valves modulate flow rate and pressure, permit shutoff, and enable backflow prevention; types include gate, ball, globe, and check, each offering distinct throttling and sealing behaviors.

Joints and couplings connect lengths of pipe, accommodate thermal expansion, and permit alignment, with soldered, threaded, flanged, and compression methods chosen for strength and serviceability.

Fittings—elbows, tees, reducers, and adapters—redirect, branch, or change diameter, minimizing turbulence when properly sized and installed.

Proper selection guarantees predictable performance.

Common Causes of Leaks, Clogs, and Low Pressure : Diagnose and Fix Them at Home

When a home’s plumbing shows damp spots, slow drains, or weak taps, these symptoms usually trace to a handful of common problems: worn seals and loose fittings that cause leaks, buildup and foreign objects that block flow, and pressure losses from partial obstructions, supply issues, or failing fixtures.

A quick diagnosis isolates visible drips, tests pressure at fixtures, and inspects drains. Simple fixes include tightening fittings, replacing washers, snaking drains, and flushing lines; stubborn problems require valve replacement or professional attention.

Preventive measures—filter screens, routine inspections, and avoiding grease—reduce recurrence.

- Tighten/replace seals and fittings

- Clear buildup and snags

- Test/repair pressure sources

Conclusion

Like a city’s arteries, a home’s water pipes carry life by balancing pressure, flow, and the parts that shape them. When pipes narrow, bend, or leak, the current falters; valves and fittings act as traffic signals, steering and stopping the stream. Understanding materials, sizes, and common faults lets one diagnose clogs or low pressure and mend them before small drips become floods—keeping the household’s circulatory system healthy and humming.