What Is Pipe Dope? Purpose, Types, and Plumbing Applications

In the world of plumbing, there’s a seemingly unassuming yet essential product that plays a crucial role in ensuring the integrity and functionality of pipe systems – pipe dope. Whether you’re a professional plumber, a DIY enthusiast, or simply someone curious about the inner workings of your home’s plumbing, understanding the purpose, types, and applications of pipe dope can be invaluable.

In this comprehensive blog post, we’ll delve into the world of pipe dope, exploring its purpose, the different types available, and its various applications in the plumbing industry. By the end of this article, you’ll have a better understanding of this indispensable tool and how it can help you tackle your plumbing projects with confidence.

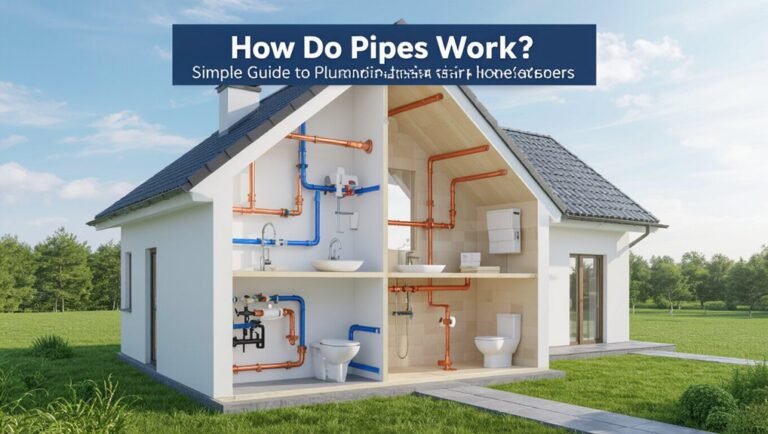

What is Pipe Dope?

Pipe dope, also known as pipe thread sealant or thread compound, is a specialized lubricant and sealant used in the installation and maintenance of threaded pipe fittings. It is designed to create a tight, leak-proof seal between the threads of pipes, valves, and other plumbing components, ensuring a secure and reliable connection.

The primary function of pipe dope is to prevent leaks by filling in the microscopic gaps and irregularities that exist between the mating threads of the pipes and fittings. This not only creates a watertight seal but also helps to prevent the threads from seizing or galling, which can make future disassembly and maintenance more challenging.

The Importance of Pipe Dope

Pipe dope plays a crucial role in the world of plumbing for several reasons:

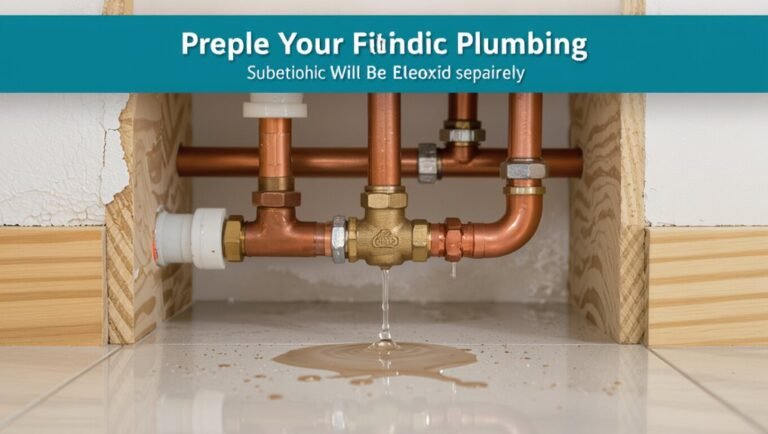

- Leak Prevention: By creating a tight seal between the threads of pipes and fittings, pipe dope helps to prevent leaks, which can lead to water damage, mold growth, and other costly issues.

- Corrosion Resistance: Many pipe dope formulations contain ingredients that help to protect the metal threads from corrosion, which can weaken the connection over time and cause leaks.

- Ease of Assembly and Disassembly: The lubricating properties of pipe dope make it easier to thread pipes and fittings together, reducing the risk of cross-threading or damage to the threads. This also makes it easier to disassemble the connection in the future, if necessary.

- Improved Reliability: A well-sealed pipe connection using pipe dope is less likely to fail over time, ensuring the long-term reliability and functionality of your plumbing system.

- Compliance with Regulations: In some cases, the use of pipe dope may be required by local building codes or industry standards to ensure the safety and integrity of plumbing installations.

Types of Pipe Dope

There are several different types of pipe dope available on the market, each with its own unique properties and applications. The most common types include:

- Teflon-Based Pipe Dope: Teflon-based pipe dope is one of the most popular and widely used types. It contains Teflon (polytetrafluoroethylene, or PTFE) particles that help to create a smooth, lubricated surface between the threads. Teflon-based pipe dope is suitable for use with a wide range of pipe materials, including metal, plastic, and even some specialty materials.

- Pipe Dope with Lubricants: Some pipe dope formulations include additional lubricants, such as silicone or graphite, to further enhance the ease of assembly and disassembly of the pipe connections.

- Anaerobic Pipe Dope: Anaerobic pipe dope is a specialized type that cures and hardens in the absence of air, forming a rigid, long-lasting seal. This type of pipe dope is often used in applications where a high-strength, vibration-resistant seal is required, such as in industrial or automotive plumbing systems.

- Pipe Dope for Gas Lines: For use with natural gas or propane lines, there are specialized pipe dope formulations that are designed to be compatible with these flammable gases and to provide a reliable, leak-proof seal.

- Pipe Dope for High-Temperature Applications: In some cases, such as in industrial or commercial plumbing systems, the pipes and fittings may be exposed to high temperatures. For these applications, there are heat-resistant pipe dope formulations that can withstand elevated temperatures without compromising the seal.

When selecting the appropriate pipe dope for your plumbing project, it’s important to consider the specific materials, pressures, and environmental conditions that the pipes and fittings will be exposed to, as well as any relevant local building codes or industry standards.

Applying Pipe Dope Correctly

Proper application of pipe dope is crucial to ensuring a secure, leak-free connection. Here are the basic steps to apply pipe dope correctly:

- Clean the Threads: Before applying the pipe dope, make sure to thoroughly clean the threads of the pipes and fittings, removing any dirt, debris, or previous sealant residue.

- Apply a Thin, Even Coat: Apply a thin, even coat of pipe dope to the male (external) threads of the pipe, taking care not to over-apply. The goal is to create a thin, continuous layer that will fill the gaps between the threads.

- Avoid Excess: Avoid applying too much pipe dope, as this can lead to excess sealant being pushed out of the connection, which can be messy and potentially clog the pipe.

- Assemble the Connection: Carefully thread the fitting onto the pipe, ensuring that the threads align properly. Use a wrench or pliers to tighten the connection, but avoid over-tightening, as this can damage the threads.

- Allow Time to Cure: Depending on the type of pipe dope used, you may need to allow some time for the sealant to fully cure and harden before pressurizing the system. Refer to the manufacturer’s instructions for the recommended curing time.

It’s important to note that the specific application instructions may vary slightly depending on the type of pipe dope and the materials being used. Always follow the manufacturer’s recommendations to ensure the best possible results.

Plumbing Applications of Pipe Dope

Pipe dope has a wide range of applications in the plumbing industry, including:

- Threaded Pipe Fittings: Pipe dope is commonly used when installing and connecting threaded pipe fittings, such as elbows, tees, unions, and valves, to create a secure, leak-proof seal.

- Flexible Hose Connections: Pipe dope can also be used to seal the threaded connections between flexible hoses and their corresponding fittings, helping to prevent leaks and maintain the integrity of the connection.

- Gas Line Installations: For natural gas or propane lines, specialized pipe dope formulations are used to ensure a safe, reliable seal that can withstand the pressures and flammable nature of these gases.

- Industrial and Commercial Plumbing: In industrial and commercial settings, where plumbing systems may be subjected to higher pressures, temperatures, or vibrations, specialized pipe dope formulations are often used to ensure the long-term reliability and safety of the installation.

- Plumbing Repairs and Maintenance: Pipe dope is also commonly used during plumbing repairs and maintenance, such as when disassembling and reassembling threaded connections, to help prevent future leaks and ensure the proper functioning of the system.

Regardless of the specific application, the use of the right type of pipe dope can help to ensure the long-term performance and safety of your plumbing system.

Conclusion

Pipe dope is an essential tool in the world of plumbing, playing a crucial role in creating secure, leak-proof connections between pipes and fittings. By understanding the purpose, types, and proper application of pipe dope, you can ensure the reliability and functionality of your plumbing system, whether you’re a professional plumber or a DIY enthusiast.

Remember, when it comes to pipe dope, it’s important to choose the right product for your specific application and to follow the manufacturer’s instructions carefully. With the right pipe dope and proper installation techniques, you can tackle your plumbing projects with confidence and enjoy the peace of mind that comes with a well-sealed, leak-free system.