What Is a Stand Pipe? Definition and Uses in Home Plumbing

A stand pipe is a vertical plumbing system designed for efficient water delivery in buildings, especially for fire protection and drainage. It is essential for transporting wastewater from various household fixtures and preventing clogs. Stand pipes often include important components such as valves and cleanouts for maintenance. Understanding the different types and their functions is significant for effective plumbing management. Discovering more about their installation, maintenance, and regulatory considerations can enhance home plumbing knowledge.

Definition of a Stand Pipe

A standpipe is a vertical pipe system designed to deliver water to various points within a building or structure, primarily for fire protection and emergency situations.

Often incorporated into larger plumbing systems, standpipes provide a reliable source of water that can be accessed quickly in emergencies. These systems can be equipped with hose connections, allowing firefighters or building personnel to connect hoses directly to the standpipe for rapid deployment of water.

Standpipes can be either wet or dry, depending on whether they are filled with water at all times or only during emergencies.

The presence of a standpipe can greatly enhance a building’s safety measures, ensuring that adequate water supply is readily available when needed.

History of Stand Pipes in Plumbing

The development of standpipes in plumbing can be traced back to historical advancements in fire safety and water distribution systems. In ancient civilizations, such as Rome and Greece, rudimentary forms of standpipes were employed to supply water for public baths and fountains.

As urban areas expanded in the 19th century, the demand for reliable fire protection led to the implementation of more sophisticated standpipe systems in buildings. The introduction of municipal water systems further enhanced their design, allowing for improved pressure and flow rates.

Throughout the 20th century, standpipes evolved to meet modern safety regulations, becoming integral in high-rise construction. Today, they serve essential roles in both firefighting and general plumbing, reflecting the ongoing evolution of water management practices.

Types of Stand Pipes

The types of stand pipes can be categorized into three main forms: vertical stand pipes, horizontal stand pipes, and drainage stand pipes.

Each type serves distinct functions and is utilized in various plumbing applications.

Understanding these differences is essential for effective system design and maintenance.

Vertical Stand Pipes

Vertical stand pipes play an important role in various applications, particularly in fire protection systems. These pipes are typically installed vertically to transport water from a source to different levels of a building. Their design allows for efficient water distribution, guaranteeing that fire hoses have quick access to necessary water supplies in emergencies. Vertical stand pipes also serve as a crucial component in plumbing systems, promoting adequate drainage and waste removal. The following table summarizes key characteristics of vertical stand pipes:

| Characteristic | Description | Importance |

|---|---|---|

| Orientation | Installed vertically | Efficient water flow |

| Function | Water transport and drainage | Supports fire safety |

| Material | Often made of steel or PVC | Durability and reliability |

| Maintenance | Regular checks required | Prevents blockages |

| Installation | Requires professional expertise | Guarantees compliance |

Horizontal Stand Pipes

Horizontal stand pipes serve as another vital component in water distribution systems, complementing vertical stand pipes.

These pipes are typically installed horizontally to facilitate the movement of water across various sections of a building, allowing for efficient distribution to multiple fixtures. They are often used in scenarios where changes in elevation are not necessary, making them ideal for connecting appliances and fixtures located on the same level.

Horizontal stand pipes can also help maintain consistent water pressure throughout a plumbing system. Proper installation and maintenance of these pipes are important to prevent leaks and guarantee peak performance, contributing to the overall reliability of a home’s plumbing infrastructure.

Understanding their function aids homeowners in managing their plumbing systems effectively.

Drainage Stand Pipes

Drainage stand pipes play an essential role in managing wastewater in plumbing systems. These vertical pipes serve to transport and direct excess water and sewage away from homes, ensuring proper drainage and preventing potential flooding.

Typically made from durable materials like PVC or cast iron, drainage stand pipes are designed to withstand the pressures of wastewater flow. They connect to the building’s sewer system and can be equipped with venting features to allow air circulation, preventing siphoning and promoting efficient drainage.

Additionally, drainage stand pipes can be found in various sizes and configurations, tailored to fit the specific needs of a plumbing system. Their effective functioning is vital for maintaining hygiene and overall home safety.

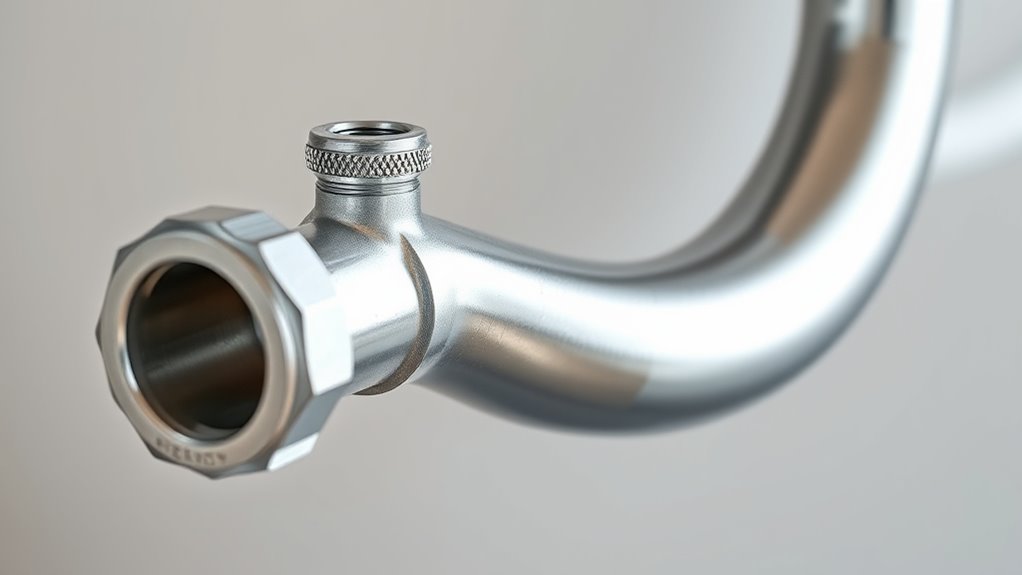

Components of a Stand Pipe

A stand pipe is composed of several essential components that work together to facilitate fluid management in various systems. The primary element is the vertical pipe itself, which is designed to transport liquids efficiently.

Attached to the top of the stand pipe is often a cap or cover that prevents debris from entering the system while allowing for venting. Additionally, there may be a valve mechanism located at the base, enabling controlled flow and drainage.

Supporting structures, such as brackets or clamps, secure the stand pipe in position, guaranteeing stability. In some cases, a cleanout fitting is included for maintenance purposes, allowing for easy access to remove blockages.

Together, these components guarantee the effective operation of the stand pipe in plumbing systems.

How Stand Pipes Function

While various systems utilize stand pipes for fluid management, their primary function remains consistent: to facilitate the smooth movement of liquids. Stand pipes operate by maintaining a vertical column of liquid, which allows for pressure regulation and flow control. They serve as conduits, directing liquids from one point to another while minimizing turbulence and backflow.

The following table illustrates the key aspects of stand pipe functionality:

| Aspect | Description |

|---|---|

| Pressure Control | Maintains consistent flow pressure |

| Flow Direction | Directs liquid to desired locations |

| Turbulence Minimization | Reduces flow disruption |

These fundamental principles guarantee that stand pipes effectively manage fluid dynamics in various plumbing applications.

Common Uses of Stand Pipes in Homes

Stand pipes play an essential role in residential plumbing systems, serving various important functions.

One common use is as a vertical conduit for waste water, allowing for efficient drainage from sinks, bathtubs, and toilets. They help maintain proper water flow, preventing clogs and ensuring effective waste disposal.

Additionally, stand pipes are often utilized in laundry rooms to accommodate washing machines, connecting the appliance to the home’s plumbing system.

In some instances, they can also serve as access points for cleaning and maintenance, facilitating easy reach for plumbers to inspect or clear blockages.

Stand Pipes in Drainage Systems

Stand pipes play a vital role in drainage systems by providing a vertical conduit for wastewater and stormwater management.

Their installation requires careful consideration of factors such as location, height, and connection to existing piping.

Understanding these elements is essential for ensuring efficient drainage and preventing potential issues.

Purpose of Stand Pipes

In drainage systems, stand pipes serve an essential role in managing excess water and ensuring effective flow control. These vertical pipes allow for the collection and discharge of wastewater, preventing potential backups and flooding.

By maintaining an appropriate water level, stand pipes help to regulate pressure within the drainage system. They also facilitate air circulation, which is vital for proper drainage function and reducing the risk of odor buildup.

Additionally, stand pipes provide access points for maintenance and inspection, ensuring that any blockages can be identified and addressed promptly. Their design is critical for promoting the overall efficiency and longevity of drainage systems, ultimately safeguarding properties from water damage and related issues.

Installation Considerations

When planning the installation of stand pipes in drainage systems, several crucial factors must be considered to guarantee ideal functionality and compliance with local regulations.

First, the diameter and height of the stand pipe should align with the expected flow rates and drainage requirements. Proper location is critical; the stand pipe must be easily accessible for maintenance and positioned to minimize the risk of blockages.

Additionally, it is important to verify that the stand pipe is adequately vented to prevent siphoning and maintain proper air pressure. Materials used for construction must withstand local environmental conditions and meet plumbing codes.

Finally, proper sealing and connection to the drainage system are essential to prevent leaks and guarantee long-term performance.

Stand Pipes for Sump Pumps

Although sump pumps are designed to manage excess water, the effectiveness of their operation can significantly depend on the installation of a stand pipe. A stand pipe serves as a vertical conduit that directs water away from the sump pump and into the drainage system.

It helps maintain an ideal water level within the sump pit, preventing the pump from cycling too frequently. By providing a dedicated pathway for water, the stand pipe minimizes the risk of backflow and guarantees efficient water removal.

Proper sizing and placement are vital, as an incorrectly installed stand pipe can lead to blockages or insufficient drainage. Consequently, attention to detail in the installation process is essential for maximizing the sump pump’s performance.

Advantages of Using Stand Pipes

Stand pipes offer several advantages that enhance the efficiency of sump pump systems. One significant benefit is their ability to maintain a consistent water level in the sump pit, preventing the pump from running dry and prolonging its lifespan.

Additionally, stand pipes help to direct water away from the foundation, reducing the risk of basement flooding and structural damage. Their design allows for easy access during maintenance and inspection, ensuring that any potential issues can be promptly addressed.

Moreover, stand pipes can improve overall drainage efficiency by minimizing the risk of clogs and ensuring smooth water flow.

Stand Pipe Installation Process

The installation process of a stand pipe requires careful planning and the right tools and materials.

A step-by-step guide can help guarantee a successful setup while highlighting common installation mistakes to avoid.

Understanding these elements is essential for achieving peak functionality and safety.

Required Tools and Materials

Proper installation of a stand pipe necessitates a specific set of tools and materials to guarantee efficiency and safety.

Essential tools include a pipe cutter or hacksaw for cutting the stand pipe to the desired length, a wrench for tightening fittings, and a level to verify proper alignment. Additionally, a measuring tape is vital for accurate measurements.

The materials required typically consist of the stand pipe itself, which is usually PVC or ABS plastic, along with appropriate connectors and fittings to connect the pipe to the drainage system. Pipe cement or adhesive may also be needed for secure bonding.

Safety gear, such as gloves and goggles, is advisable to protect against potential hazards during installation.

Step-by-Step Installation Guide

After gathering the necessary tools and materials, the installation of a stand pipe can commence.

First, the desired location for the stand pipe should be identified, typically near a drain or washing machine. Next, the existing plumbing must be assessed to guarantee compatibility.

A section of the drain line is then cut, and the stand pipe is positioned vertically, making sure it is level. The connections should be secured using appropriate fittings, and PVC cement may be applied to guarantee a watertight seal.

Once everything is connected, the system should be tested for leaks. Finally, the area should be cleaned up, removing any debris or tools used during installation.

Proper installation guarantees peak performance and longevity of the stand pipe.

Common Installation Mistakes

Many homeowners encounter common pitfalls during the stand pipe installation process that can lead to significant issues down the line.

One frequent mistake is failing to guarantee proper alignment; a misaligned stand pipe can cause blockages and leaks.

Additionally, inadequate sealing at joints often results in water damage, as loose connections may allow water to escape.

Another common error involves neglecting local plumbing codes, which can lead to fines or required rework.

Homeowners also sometimes underestimate the importance of selecting the correct diameter for the stand pipe, which can affect drainage capacity.

Finally, overlooking the need for proper venting can create pressure issues, ultimately compromising the system’s efficiency and functionality.

Avoiding these mistakes is vital for a successful installation.

Maintenance Tips for Stand Pipes

Regular maintenance of stand pipes is essential for guaranteeing their efficient operation and longevity. Homeowners should routinely check for any visible signs of wear or damage. Cleaning the area around the stand pipe prevents debris accumulation, which can obstruct water flow. Regularly inspecting joints and connections helps to identify potential leaks before they escalate.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for cracks or rust |

| Cleaning | Quarterly | Remove dirt and debris |

| Joint Inspection | Biannually | Guarantee tight connections |

Troubleshooting Stand Pipe Issues

Even with routine maintenance, issues can arise with stand pipes that require prompt attention.

Common problems include clogs, which can prevent proper drainage, leading to water backup. Homeowners should inspect the stand pipe for blockages by checking the inlet and outlet areas.

Additionally, leaks may occur due to deteriorating seals or connections, necessitating immediate repair to prevent water damage.

Unusual noises during drainage can indicate air trapped in the system or a vent issue, warranting further investigation.

Finally, if water levels in the stand pipe fluctuate unexpectedly, this could signal a problem with the home’s drainage system or a malfunctioning sump pump.

Addressing these issues promptly can help maintain ideal function and prevent more severe plumbing complications.

Differences Between Stand Pipes and Other Plumbing Fixtures

Stand pipes serve a specific purpose in plumbing, primarily focusing on vertical water distribution.

Unlike typical drainage systems, which manage wastewater, stand pipes are often employed in unique applications such as fire protection and high-rise buildings.

Understanding these differences highlights the critical roles that various plumbing fixtures play in overall water management.

Stand Pipe Functionality

While many plumbing fixtures serve distinct purposes within a building’s infrastructure, stand pipes uniquely function as vertical conduits that facilitate the movement of water for fire protection and other emergency situations.

Unlike standard faucets or sinks that deliver water for daily use, stand pipes are specifically designed to provide immediate access to water at higher elevations. This functionality is essential during emergencies, allowing firefighters to connect hoses quickly and efficiently.

Additionally, stand pipes differ from drainage systems, as they do not remove wastewater but rather supply pressurized water. Their strategic placement in buildings guarantees that water is readily available where it is most needed, underscoring their critical role in safety and emergency preparedness.

Comparison With Drainage Systems

Although both stand pipes and drainage systems are essential components of a building’s plumbing infrastructure, they serve fundamentally different purposes.

Stand pipes are vertical pipes designed primarily to transport water to various fixtures, ensuring adequate water pressure for activities such as firefighting or general domestic use.

In contrast, drainage systems focus on the removal of wastewater and stormwater from a building, preventing flooding and ensuring proper sanitation.

While stand pipes are integral for water supply, drainage systems are critical for waste management.

Their design and functionality reflect these roles, with stand pipes often located in accessible areas for maintenance, whereas drainage systems are typically concealed beneath floors or in walls, emphasizing their distinct contributions to plumbing efficiency.

Unique Plumbing Applications

The distinctive role of stand pipes within plumbing systems sets them apart from other fixtures such as faucets, toilets, and bathtubs.

Unlike these common fixtures, stand pipes primarily serve as vertical conduits for water drainage and are often utilized in specific applications, including stormwater management and emergency overflow systems. They are designed to accommodate high volumes of water, ensuring efficient drainage in scenarios where traditional fixtures may not suffice.

Additionally, stand pipes can be integrated into fire protection systems, allowing for quick access to water in emergencies. Their unique structure and purpose highlight their importance in maintaining plumbing efficiency and safety, distinguishing them from standard household plumbing components.

Building Codes and Regulations for Stand Pipes

Building codes and regulations for stand pipes are essential to guarantee fire safety and effective emergency response in various structures.

These codes dictate the design, installation, and maintenance of stand pipes, ensuring they function correctly during emergencies. They typically specify the required materials, pipe sizes, and pressure ratings to accommodate fire department equipment.

Compliance with local and national standards, such as those set by the National Fire Protection Association (NFPA), is vital for legal and safety purposes. Inspections and regular maintenance are also mandated to prevent malfunctions.

Future Trends in Stand Pipe Design and Usage

As fire safety technology evolves, innovations in stand pipe design and usage are set to enhance their effectiveness and reliability in emergency situations.

Future trends focus on integrating advanced materials and smart technologies, ensuring a more robust firefighting infrastructure.

Key developments include:

- Flexible materials that can withstand extreme temperatures and pressures.

- Integrated monitoring systems that provide real-time data on water flow and pipe integrity.

- Modular designs allowing for easy installation and maintenance in various building layouts.

- Automated controls that enable rapid deployment during emergencies, minimizing response time.

These advancements not only aim to improve firefighting capabilities but also promote greater safety for occupants and first responders alike, transforming the role of stand pipes in modern fire protection strategies.

Conclusion

In summary, the stand pipe serves as an essential component in home plumbing systems, bridging the past and future of water management. Coincidentally, as urban landscapes evolve and sustainability becomes paramount, the stand pipe’s design is poised for transformation. This intersection of tradition and innovation underscores its enduring relevance, ensuring that homeowners can effectively manage water flow while adhering to modern regulations. Ultimately, the stand pipe remains a proof of the ingenuity of plumbing solutions throughout history.